Scientists Create Magnesium Composite With Prodigious Load Bearing Capabilities

A new Magnesium-Silicon Carbide composite has been created by the scientists at the University of California, Los Angeles (UCLA), which boasts amazing load bearing capabilities, along with being light-weight and surprisingly durable.

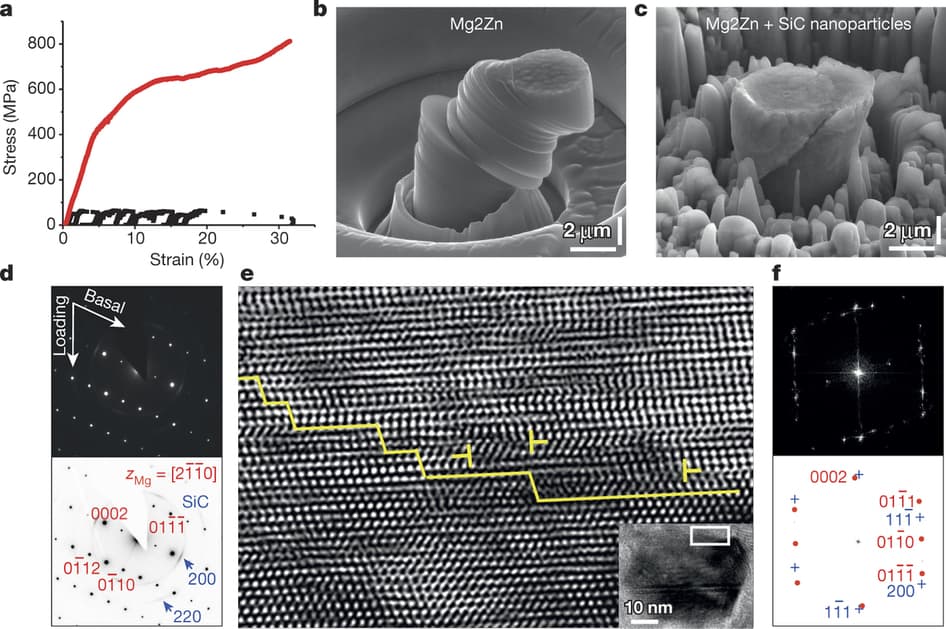

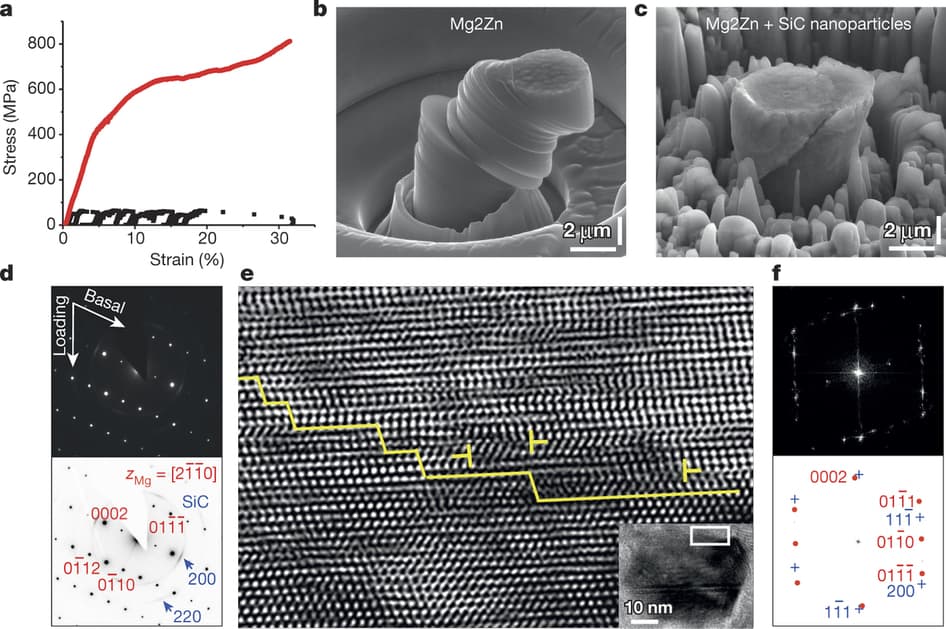

Figure showing microscopic view and arrangement of particles

The researchers wanted to combine the properties of magnesium, which is light but comparatively weaker than other metals, and silicon carbide, which is very hard, but brittle, into one material. The resulting composite is 14% silicon carbide and 86% magnesium by volume.

The composite was created by intermixing Silicon-Carbide nano-particles with Magnesium-Zinc alloy in its molten state. The nano-particles were allowed to disperse evenly throughout the mix, before it was cooled and compressed at high pressure. The evenly distributed nano-particles reinforce the metal without making it too brittle, and gives it a higher modulus of strength. The resulting material combined the properties of magnesium and silicon carbide, and therefore exhibits increased strength, temperature resistance, stiffness, and plasticity.

In other words, it is very durable and deceptively strong; a small amount of this material can support a proportionally huge amount of weight/load. That coupled with the fact that it is very light (lighter than aluminum or titanium), makes it a very capable structural material.

The uses of this new composite could be immense, as the world is in constant lookout materials which are lighter but stronger, cheaper but more capable. The composite could possibly replace titanium and aluminum in the aircraft and space industries, as it does not weigh as much as the other metals, but is stronger.

The price of production of the composite hasn’t been accurately scaled up for industrial use yet, but nevertheless, there is little doubt that this new material will have a growing presence in a lot of fields henceforth.

Source: #-Link-Snipped-#, #-Link-Snipped-#

Figure showing microscopic view and arrangement of particles

The researchers wanted to combine the properties of magnesium, which is light but comparatively weaker than other metals, and silicon carbide, which is very hard, but brittle, into one material. The resulting composite is 14% silicon carbide and 86% magnesium by volume.

The composite was created by intermixing Silicon-Carbide nano-particles with Magnesium-Zinc alloy in its molten state. The nano-particles were allowed to disperse evenly throughout the mix, before it was cooled and compressed at high pressure. The evenly distributed nano-particles reinforce the metal without making it too brittle, and gives it a higher modulus of strength. The resulting material combined the properties of magnesium and silicon carbide, and therefore exhibits increased strength, temperature resistance, stiffness, and plasticity.

In other words, it is very durable and deceptively strong; a small amount of this material can support a proportionally huge amount of weight/load. That coupled with the fact that it is very light (lighter than aluminum or titanium), makes it a very capable structural material.

The uses of this new composite could be immense, as the world is in constant lookout materials which are lighter but stronger, cheaper but more capable. The composite could possibly replace titanium and aluminum in the aircraft and space industries, as it does not weigh as much as the other metals, but is stronger.

The price of production of the composite hasn’t been accurately scaled up for industrial use yet, but nevertheless, there is little doubt that this new material will have a growing presence in a lot of fields henceforth.

Source: #-Link-Snipped-#, #-Link-Snipped-#

0