Princeton Engineers Achieve Significant Breakthrough In Improving LEDs

LED systems are already a hot property all over the world. From portable electronics, smartphones to home lighting solutions, LEDs can replace conventional lighting in almost all areas. A recent development over normal LEDs, the carbon-based Organic Light Emitting Diodes (OLEDs), which are brighter, thinner, lighter, more flexible and are less power hungry are already being used in various applications. And now, the researchers at Princeton have made a significant breakthrough in improving the brightness, efficiency and clarity of LEDs. Moreover, the scientists claim that their methods can produce similar results in normal (silicon-based) LEDs commonly used today.

The team of scientists at the Electrical Engineering department at Princeton headed by professor Stephen Chou increased the increased the brightness and efficiency of LEDs made of organic materials (flexible carbon-based sheets) by a staggering 57 percent. A normal LED emits only 2-4 percent of the light it generates. Displays have also benefited from this research and have shown a 400 percent better picture quality over their normal, commercial counterparts. Also, the team has claimed that the technology used to manufacture these is simple and cheap.

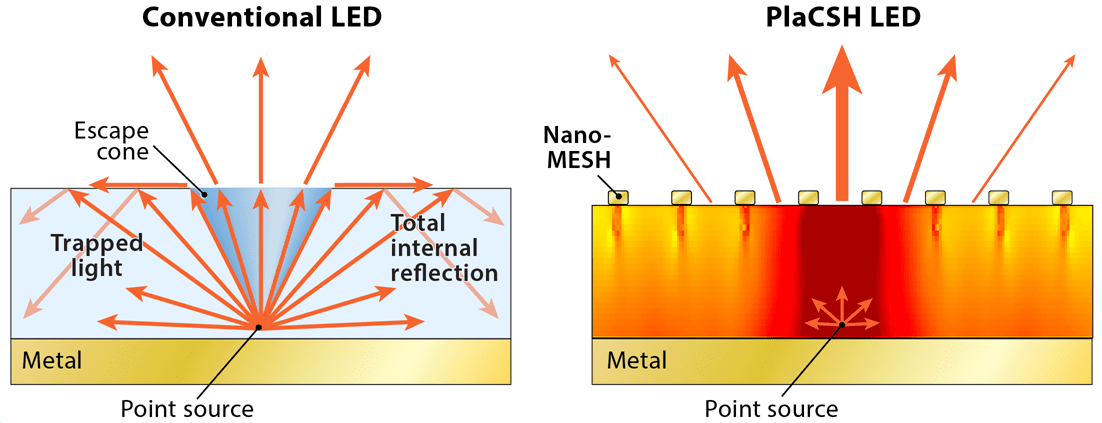

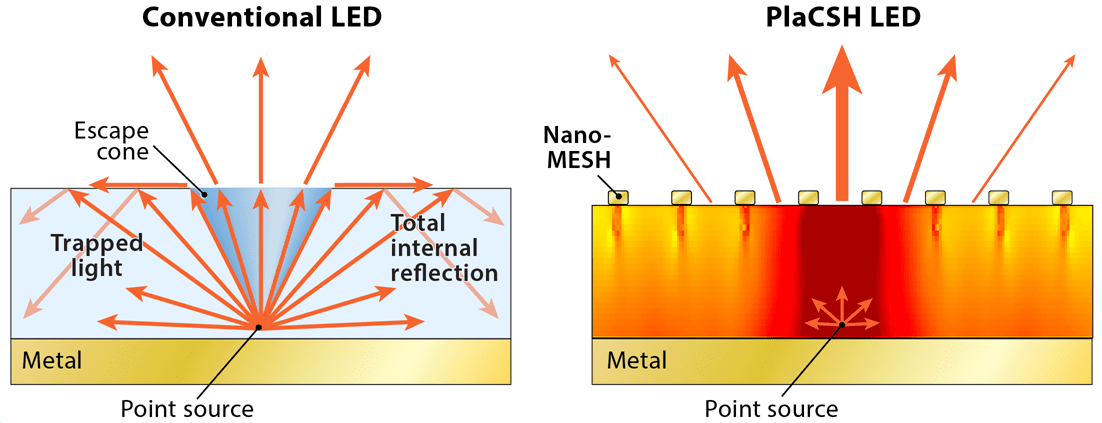

The problem of conventional LEDs is that light often gets trapped within it due to a phenomenon called 'total internal reflection'. Princeton engineers solved this problem by placing a nanotechnology structure called PlaCSH (plasmonic cavity with subwavelength hole-array) over the LED in order to 'extract' more light from it. Apart from the 60 percent efficiency and a 400 percent improvement in contrast, the PlaCSH structure also relieved the LED of the heat produced due to the trapped light.

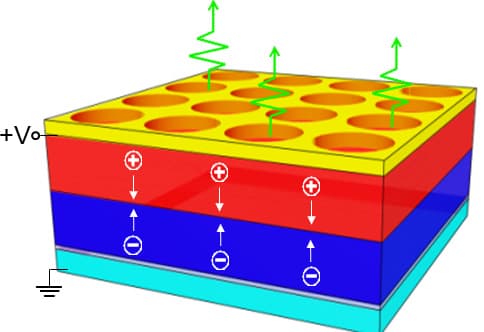

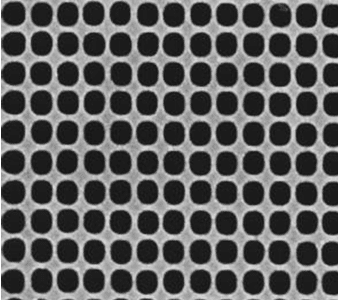

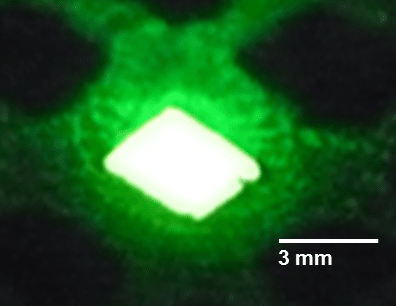

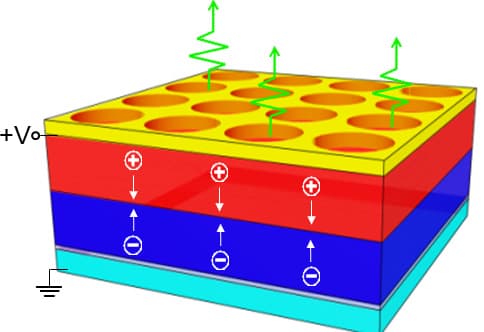

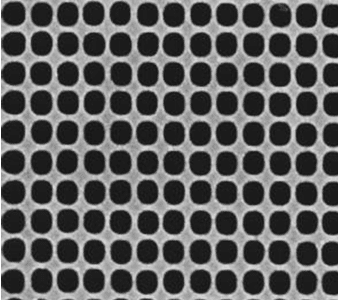

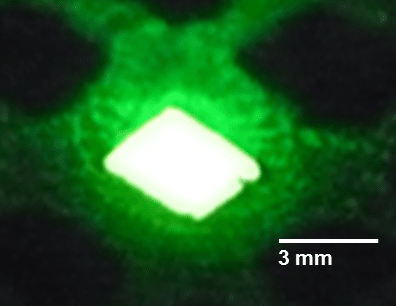

The structure has 2 layers: an outer layer of 100 nanometers width and the inner layer is 15 nanometers thick. Because of the order of size of this structure is that of light, it is able to manipulate light in a way that bulk material or non-metallic nanostructures cannot. The wires that 'extract' light are about 20 nanometers thick and are spaced about 200 nanometers apart. Professor Chou used 'nanoimprint' technology (which he invented in 1995) to manufacture the PlaCSH structure. They have successfully demonstrated the technology on green organic LEDs and now are conducting experiments on red and blue organic as well as silicon LEDs.

It is worthwhile to note that in a 2012 paper by Chou, he showed how the application of this structure to solar cells resulted in increase in absorption of light to upto 96 percent striking solar cells' surface and increased the cells' efficiency by 175 percent.

Going by the stats, the PlaCSH has definitely pushed the boundaries in the Solid State Lighting field and may be there is still more to come.

Source: #-Link-Snipped-#

The team of scientists at the Electrical Engineering department at Princeton headed by professor Stephen Chou increased the increased the brightness and efficiency of LEDs made of organic materials (flexible carbon-based sheets) by a staggering 57 percent. A normal LED emits only 2-4 percent of the light it generates. Displays have also benefited from this research and have shown a 400 percent better picture quality over their normal, commercial counterparts. Also, the team has claimed that the technology used to manufacture these is simple and cheap.

The problem of conventional LEDs is that light often gets trapped within it due to a phenomenon called 'total internal reflection'. Princeton engineers solved this problem by placing a nanotechnology structure called PlaCSH (plasmonic cavity with subwavelength hole-array) over the LED in order to 'extract' more light from it. Apart from the 60 percent efficiency and a 400 percent improvement in contrast, the PlaCSH structure also relieved the LED of the heat produced due to the trapped light.

The structure has 2 layers: an outer layer of 100 nanometers width and the inner layer is 15 nanometers thick. Because of the order of size of this structure is that of light, it is able to manipulate light in a way that bulk material or non-metallic nanostructures cannot. The wires that 'extract' light are about 20 nanometers thick and are spaced about 200 nanometers apart. Professor Chou used 'nanoimprint' technology (which he invented in 1995) to manufacture the PlaCSH structure. They have successfully demonstrated the technology on green organic LEDs and now are conducting experiments on red and blue organic as well as silicon LEDs.

Going by the stats, the PlaCSH has definitely pushed the boundaries in the Solid State Lighting field and may be there is still more to come.

Source: #-Link-Snipped-#

0