Could We 3D Print Wigs And Hair Extensions? MIT Media Lab Holds Answers

A team of engineers at the MIT Media Lab has devised a new technique that lets them quickly model (bypassing a major design step) and 3D print hair-like structures with ease. As it turns out, in the 21st century era of 3D printing, scientists have tried printing everything from a sports car to human skin. However, some objects such as hair or fur which have super fine features, require large amount of power as well as computational time to first design and then print. To overcome this issue, instead of using traditional CAD software, the MIT researchers developed a new software platform called 'Cilllia' that lets users define various parameters such as density, height, thickness, angle etc. in a matter of minutes. Software Cilllia could create thousands of hair-like structures of the resolution 50 microns, which is the width of a human hair. By adjusting various parameters, the team could 3D print arrays of fine fur on flat as well as curved surfaces.

The technology will not only be of help to print wigs and hair extensions, but also used for mimicking several natural features of hair such as adhesion, sensing and actuation. In fact, the team came up with 3 different ideas for demonstrating the possibilities.

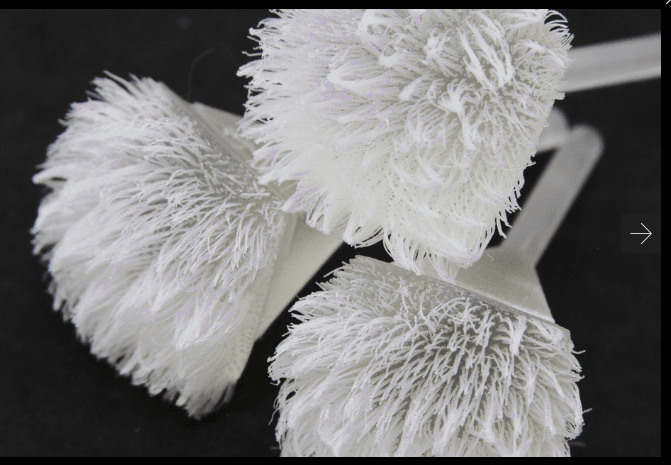

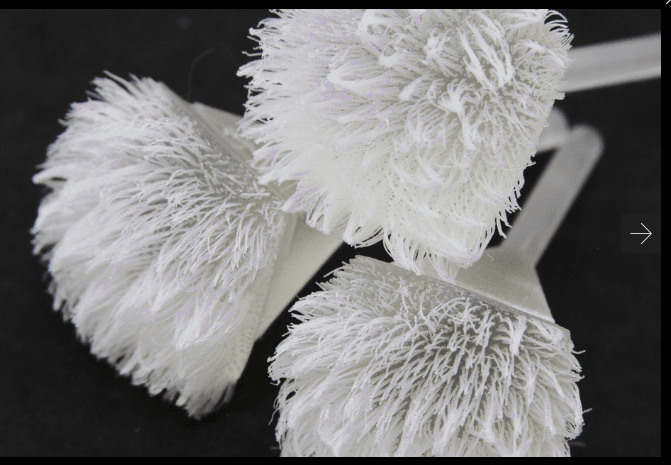

Starting with Adhesion - The team 3D printed bristle pad arrays that act just like Velcro. Depending upon the angle of the bristles, the pads will stick to each other with varying forces.

Next comes Sensing - A rabbit shaped fur was created to equip LED lights so that when the rabbit is stroked, the lights got lit up. Last but not the least, Actuation - A weight sorting table was created from panels of hair with specific heights and angles. When a small vibration force shook the panels, the hairs could move coins across the table, so that they got sorted according to the coins' weight.

The team believes that the 3D printers that we use today have a really high resolution, however we are not using the technology up to its full potential. If we take hair as a subject, it turns out that existing software would take hours to process the CAD design and the slicer program would probably crash.

Instead of using the CAD modeling technique, the MIT researchers used their newly developed software platform to model a single strand of hair by representing an elongated cone as a stack of pixels from base to the top. For changing the properties of hair such as its height, width or angle, they only had to change the pixel arrangement inside the cone.

A color-mapping technique was used to assign the three colors - red, green and blue to represent the height, width and angle respectively. An algorithm was also devised to translate the color map into a model of a hair array, which would be fed to a 3-D printer. The team was also successful in printing hair on curved surfaces.

One thing is clear that researchers are working hard towards pushing the boundaries of 3D printing. What are your thoughts about the new MIT research? Share with us in comments section below.

Source: <a href="https://news.mit.edu/2016/3-d-print-hair-0617" target="_blank" rel="noopener noreferrer">news.mit.edu</a>

The technology will not only be of help to print wigs and hair extensions, but also used for mimicking several natural features of hair such as adhesion, sensing and actuation. In fact, the team came up with 3 different ideas for demonstrating the possibilities.

Starting with Adhesion - The team 3D printed bristle pad arrays that act just like Velcro. Depending upon the angle of the bristles, the pads will stick to each other with varying forces.

Next comes Sensing - A rabbit shaped fur was created to equip LED lights so that when the rabbit is stroked, the lights got lit up. Last but not the least, Actuation - A weight sorting table was created from panels of hair with specific heights and angles. When a small vibration force shook the panels, the hairs could move coins across the table, so that they got sorted according to the coins' weight.

The team believes that the 3D printers that we use today have a really high resolution, however we are not using the technology up to its full potential. If we take hair as a subject, it turns out that existing software would take hours to process the CAD design and the slicer program would probably crash.

Instead of using the CAD modeling technique, the MIT researchers used their newly developed software platform to model a single strand of hair by representing an elongated cone as a stack of pixels from base to the top. For changing the properties of hair such as its height, width or angle, they only had to change the pixel arrangement inside the cone.

A color-mapping technique was used to assign the three colors - red, green and blue to represent the height, width and angle respectively. An algorithm was also devised to translate the color map into a model of a hair array, which would be fed to a 3-D printer. The team was also successful in printing hair on curved surfaces.

One thing is clear that researchers are working hard towards pushing the boundaries of 3D printing. What are your thoughts about the new MIT research? Share with us in comments section below.

Source: <a href="https://news.mit.edu/2016/3-d-print-hair-0617" target="_blank" rel="noopener noreferrer">news.mit.edu</a>

0