Newly Developed Strongest Titanium Alloy To Be A Boon To Automobiles

A group of researchers of Indian origin have revealed a compound made of Titanium alloy which can significantly uplift the automobile industry, in terms of fuel economy and CO2 emissions. The customized Titanium alloy is the strongest of all and is achieved by a modified arrangement of atoms as a special nanoscaled structure. Arun Devaraj and team hail from the Department of Energy's Pacific Northwest National Laboratory and has been monitoring Titanium’s internal properties, its mechanical effects and strength for a long time. The group decided to further develop the element as a novel low-cost, high strength-to-weight ratio metal and as a consequence achieved the ß-Titanium alloy.

The group was inspired by the previous work of coalescing Iron and Vanadium with Titanium which had already produced Ti185, but due to some defects it was not a commercially viable product. At that time, they had found a way to commercially produce energy efficient titanium hydride powder, which is now commonly used in the aerospace industry. The recent study in PNNL was developed on the skeleton of titanium atom arrangements, that was extensively researched and modeled using the electron microscope and atom probe tomography system.

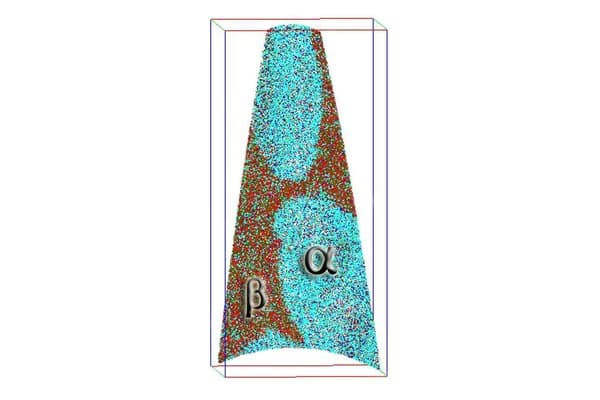

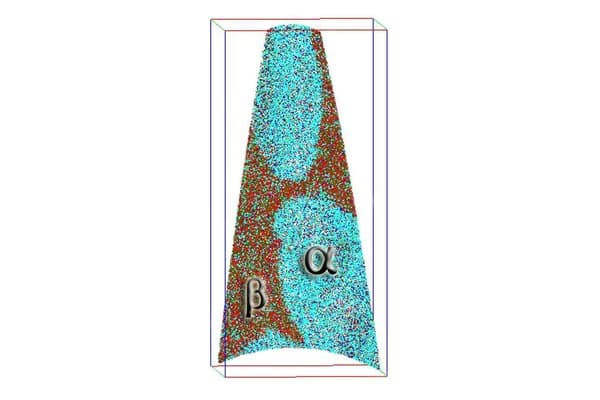

Atomic Map of Titanium

The atom probe launches one atom after another which hits the detector in a synchronized manner, resulting in light atoms approaching faster and heavy ones later. Each atom is identified and mapped according to the time taken by the atom to reach the detector. Thus, the structure was reveled and scientists realized that if the alloy is heat-treated, micron or nanoscaled precipitation regions are formed, known as alpha phase inside a matrix known as beta phase. Both the phases have extensively packed and concentrated elements.

First author Devraj explained that aluminum and titanium are keen to stick to the inner core of the alpha precipitates, whereas vanadium and iron like to gather in the beta phase matrix. This unique arrangement causes the material to achieve 10 to 15 percent increase in strength when compared to contemporary titanium alloys. The team collaborated with Ankit Srivastava, an assistant professor at Texas A&M's material science and engineering to create a mathematical model of the structure.

Researcher Devraj stressed that their future goal would be to manipulate the alloy structure and test its different properties. These artificial changes might boost their efficiency and help them to be be dendrophilic. The complete research was reported in the “Nature Communication†journal.

Watch A Closer look at a stronger Titanium:

Source: <a href="https://www.pnnl.gov/news/release.aspx?id=4264" target="_blank" rel="nofollow noopener noreferrer">PNNL: News - Low-cost and lightweight</a> | #-Link-Snipped-#

The group was inspired by the previous work of coalescing Iron and Vanadium with Titanium which had already produced Ti185, but due to some defects it was not a commercially viable product. At that time, they had found a way to commercially produce energy efficient titanium hydride powder, which is now commonly used in the aerospace industry. The recent study in PNNL was developed on the skeleton of titanium atom arrangements, that was extensively researched and modeled using the electron microscope and atom probe tomography system.

Atomic Map of Titanium

First author Devraj explained that aluminum and titanium are keen to stick to the inner core of the alpha precipitates, whereas vanadium and iron like to gather in the beta phase matrix. This unique arrangement causes the material to achieve 10 to 15 percent increase in strength when compared to contemporary titanium alloys. The team collaborated with Ankit Srivastava, an assistant professor at Texas A&M's material science and engineering to create a mathematical model of the structure.

Researcher Devraj stressed that their future goal would be to manipulate the alloy structure and test its different properties. These artificial changes might boost their efficiency and help them to be be dendrophilic. The complete research was reported in the “Nature Communication†journal.

Watch A Closer look at a stronger Titanium:

0