New 4D Printing Tech Will Leave You In Awe As It Uses 'Time' As 4th Dimension

As the world still remains spellbound about the exciting new applications in the world of 3D Printing, here's an awesome innovation from University of Wollongong & ACES researchers that has potential to stir a great revolution in the field of additive manufacturing. Called '4D Printing', the new research work talks about using external stimuli such as water or heat for changing the shape of a 3D printed object after it's completely produced. Since the shift in shape is done post production, the team uses 'time' as the 4th dimension in the new technology now called 4D printing. The new tech holds key to take 3D printing to an awesome new level where the possibilities in applications are limitless (be it construction or robotics, medicine or automation).

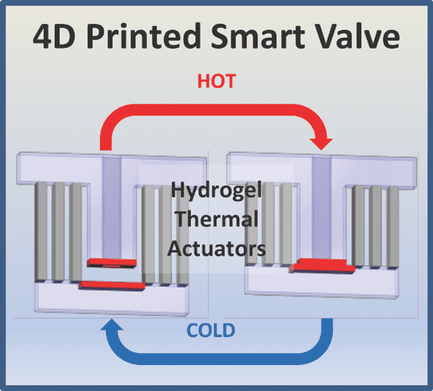

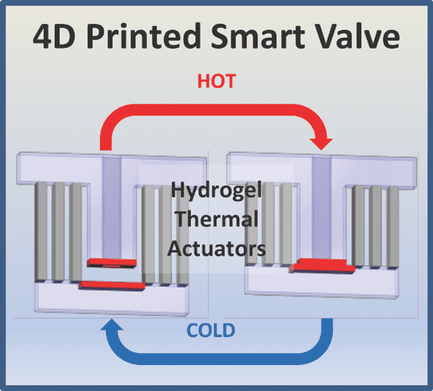

The Wollongong & ACES researchers want you to imaging a 3D printed structure that is built layer by layer, with the only modification that the materials are able to transform themselves from one shape into another. With the ability to change shape or even the function of the object on-demand and over a set period of time, 4D printing technology is extending the potential of 3D printing. By combining smart actuating and sensing materials with additive manufacturing techniques, the team has been able to successfully develop a versatile yet convenient method to manufacture custom-designed sensors. They have created a 4D printed smart valve that actuates in response to its surrounding water’s temperature.

Tapping into the field of soft robotics, the team developed a 'smart valve' by 4D printing of hydrogels that are mechanically robust and thermally actuating. The valve operates autonomously in that it closes itself when in contact with hot water. The printed hydrogels are made up of an interpenetrating network of alginate and poly(N-isopropylacrylamide). The most interesting thing about this tech is that the fully functioning device is ready to be used right from the top of the 4D printer, meaning that no separate assembly is needed.

The existing 4D printed objects use water absorption or thermal shape memory to demonstrate impressive change in shape. However, they are slow to respond and show limited reversibility. The ACES and Wollongong University researchers have built a relatively faster & reversible skeletal muscle-like linear actuation & incorporated it in a smart valve. We are only looking forward to what the future holds as additive manufacturing takes new twists and turns.

What are your thoughts on 3D and 4D printing? Share with us in comments below.

Source: #-Link-Snipped-# | #-Link-Snipped-#

The Wollongong & ACES researchers want you to imaging a 3D printed structure that is built layer by layer, with the only modification that the materials are able to transform themselves from one shape into another. With the ability to change shape or even the function of the object on-demand and over a set period of time, 4D printing technology is extending the potential of 3D printing. By combining smart actuating and sensing materials with additive manufacturing techniques, the team has been able to successfully develop a versatile yet convenient method to manufacture custom-designed sensors. They have created a 4D printed smart valve that actuates in response to its surrounding water’s temperature.

Tapping into the field of soft robotics, the team developed a 'smart valve' by 4D printing of hydrogels that are mechanically robust and thermally actuating. The valve operates autonomously in that it closes itself when in contact with hot water. The printed hydrogels are made up of an interpenetrating network of alginate and poly(N-isopropylacrylamide). The most interesting thing about this tech is that the fully functioning device is ready to be used right from the top of the 4D printer, meaning that no separate assembly is needed.

The existing 4D printed objects use water absorption or thermal shape memory to demonstrate impressive change in shape. However, they are slow to respond and show limited reversibility. The ACES and Wollongong University researchers have built a relatively faster & reversible skeletal muscle-like linear actuation & incorporated it in a smart valve. We are only looking forward to what the future holds as additive manufacturing takes new twists and turns.

What are your thoughts on 3D and 4D printing? Share with us in comments below.

Source: #-Link-Snipped-# | #-Link-Snipped-#

0