Spider Silk Set To Become Commercially Available

The amazing properties of spider web silk are known to most of us, well, through General Knowledge textbooks and through "Fun Facts/Did You Know?" sections on the back cover pages of our notebooks only. Spider silk is by weight five times stronger than steel and three times tougher than Kevlar. Spider silk also has antimicrobial properties and is, interestingly, not rejected by human body. Its thermal conductivity is similar to that of copper but its mass density is one-seventh of copper’s, making it a potential heat management material.

Despite all this major chemical companies like the French DuPont(who developed Kevlar) and German chemical kingpin BASF had pulled the plug on their spider silk research labs. The difficulty in synthesizing the protein which gives the spider silk its strength, the need to invent new spinning systems for the silk and the insolubility of spider silk in water were a few reasons among others for the companies to opt out of this research. Needless to say, the spider silk research throughout the world had received a major setback.

Despite all this major chemical companies like the French DuPont(who developed Kevlar) and German chemical kingpin BASF had pulled the plug on their spider silk research labs. The difficulty in synthesizing the protein which gives the spider silk its strength, the need to invent new spinning systems for the silk and the insolubility of spider silk in water were a few reasons among others for the companies to opt out of this research. Needless to say, the spider silk research throughout the world had received a major setback.

But things may change sooner rather than later.

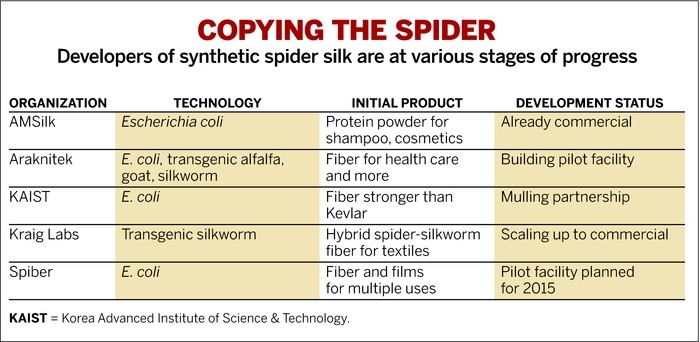

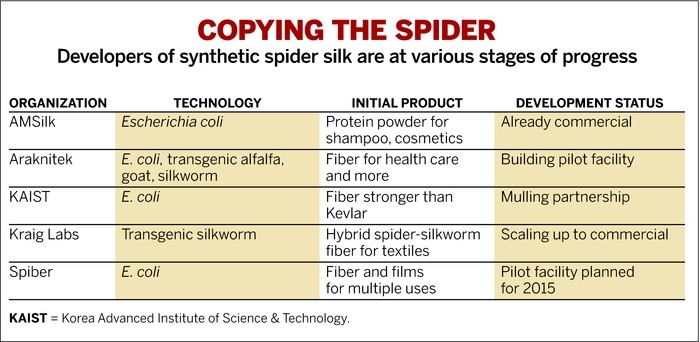

Last year, Utah State University's Synthetic Spider Silk Lab was awarded $ 1.1 M by the US Navy and US National Science Foundations for research purposes. In past few months, smaller firms in Europe have taken baby steps in spider silk protein commercialization. The German firm AMSilk has begun supplying protein to producers of shampoos and cosmetics. The company claims that the spider silk makes skin feel 'supersmooth' and also the silk adheres to keratin, natural protein in hair which makes damaged hair look and feel smooth and silky. The company hopes to launch a wound-healing spray in May.

South Korea’s Korea Advanced Institute of Science & Technology (KAIST) and Spiber, a Japanese start-up are developing techniques to manufacture spider silk using E.coli. The humble E.coli has been used in biosynthesis of spider silk since 1995 and is probably the most commercially viable method for mass production of spider silk over other techniques. Although not currently in market, both the organisations hope that theirs is a method that is fit for mass production of silk. Spiber has raised $ 8.1 Million and it plans to open a pilot facility by 2015 that is capable of producing 100 kg of spider silk fiber per month. A single gram of protein is enough to produce fibres 5.6 miles long, says Spiber. KAIST is developing a high-molecular-weight silk stronger than Kevlar.

Other notable spider silk companies, mostly startups, are the Utah State University-funded Araknitek and Kraig Labs, among others. Araknitek is developing four different hosts that carry the spider silk genes: goats, silkworms, E. coli, and alfalfa. The team has managed to increases the expression of spider silk in E. coli by a factor of five. Kraig Labs has, in one step, jumped straight from proteins to fibre production by inserting genes from spiders into silkworms. Prodigious, isn't it?

A brief description of the above discussion is given in table below:

From <a href="https://www.crazyengineers.com/threads/seashell-inspired-glass-developed-by-mcgill-university-will-bend-but-wont-crack.73068">Seashell Inspired Glass Developed By McGill University Will Bend But Won't Crack</a> and #-Link-Snipped-# to #-Link-Snipped-#, nature inspires man to scale new heights in technology. And so the scene is "Spiderman 2" where Spiderman stops a train full of people does not seem so far-fetched or futuristic, or wait, does it?

Images and News Source:#-Link-Snipped-#

But things may change sooner rather than later.

Last year, Utah State University's Synthetic Spider Silk Lab was awarded $ 1.1 M by the US Navy and US National Science Foundations for research purposes. In past few months, smaller firms in Europe have taken baby steps in spider silk protein commercialization. The German firm AMSilk has begun supplying protein to producers of shampoos and cosmetics. The company claims that the spider silk makes skin feel 'supersmooth' and also the silk adheres to keratin, natural protein in hair which makes damaged hair look and feel smooth and silky. The company hopes to launch a wound-healing spray in May.

South Korea’s Korea Advanced Institute of Science & Technology (KAIST) and Spiber, a Japanese start-up are developing techniques to manufacture spider silk using E.coli. The humble E.coli has been used in biosynthesis of spider silk since 1995 and is probably the most commercially viable method for mass production of spider silk over other techniques. Although not currently in market, both the organisations hope that theirs is a method that is fit for mass production of silk. Spiber has raised $ 8.1 Million and it plans to open a pilot facility by 2015 that is capable of producing 100 kg of spider silk fiber per month. A single gram of protein is enough to produce fibres 5.6 miles long, says Spiber. KAIST is developing a high-molecular-weight silk stronger than Kevlar.

Other notable spider silk companies, mostly startups, are the Utah State University-funded Araknitek and Kraig Labs, among others. Araknitek is developing four different hosts that carry the spider silk genes: goats, silkworms, E. coli, and alfalfa. The team has managed to increases the expression of spider silk in E. coli by a factor of five. Kraig Labs has, in one step, jumped straight from proteins to fibre production by inserting genes from spiders into silkworms. Prodigious, isn't it?

A brief description of the above discussion is given in table below:

From <a href="https://www.crazyengineers.com/threads/seashell-inspired-glass-developed-by-mcgill-university-will-bend-but-wont-crack.73068">Seashell Inspired Glass Developed By McGill University Will Bend But Won't Crack</a> and #-Link-Snipped-# to #-Link-Snipped-#, nature inspires man to scale new heights in technology. And so the scene is "Spiderman 2" where Spiderman stops a train full of people does not seem so far-fetched or futuristic, or wait, does it?

Images and News Source:#-Link-Snipped-#

0