Scientists "weave" 3D nanomaterials for the first time - Could help create clean fuel

Scientists from the U.S. Department of Energy (DOE)’s Lawrence Berkeley National Laboratory (Berkeley Lab) have joined hands with the University of California, Berkeley to weave the first three-dimensional covalent organic frameworks (COFs) from helical organic threads. Nano-engineering using 3D printing technology is a most common process, and for the first time scientists have been able to knit nano-materials together, which could be called a boon to the otherwise monotonous processing technique. The full description of their work was reported in the paper titled “Weaving of organic threads into a crystalline covalent organic frameworkâ€, published in the American Association for the Advancement of Science Journal.

Covalent Organic Framework is an organic structure developed in the crystalline framework, having strong covalent bonds between its sub building blocks. Having light elements interweaved, the structure shows storage properties of gasses such as Methane, Hydrogen, Carbon and features useful optical properties. As an application, COFs have been used to capture carbon dioxide and#-Link-Snipped-#

2D diagram of COF

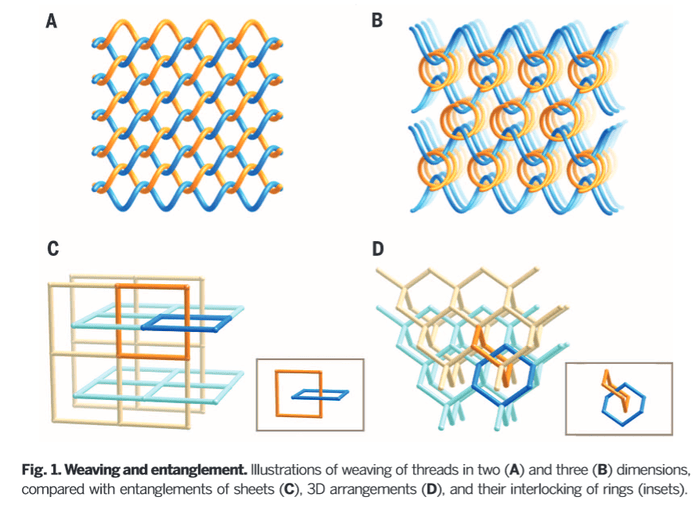

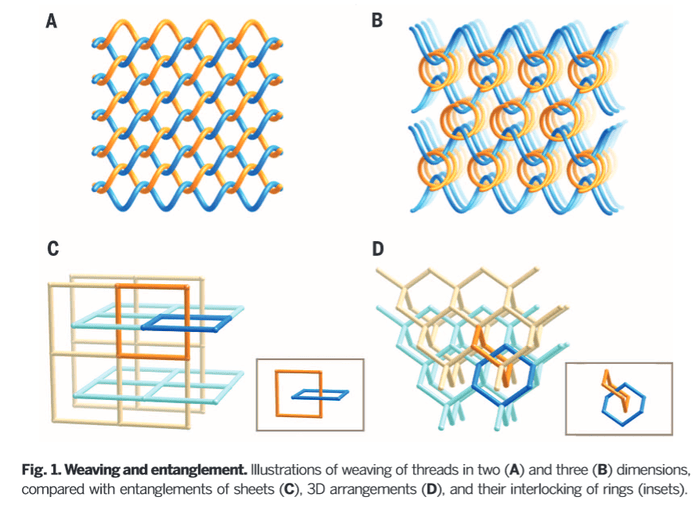

The newly weaved COF is malleable, flexible and shows great resilience as compared to previous COFs. Its woven structures can also be made in the form of nanoparticles or polymers and sports many degrees of freedom without destabilising the overall structure. Omar Yaghi, a chemist and co-director of the Kavli Energy NanoScience Institute explained that their team eventually introduced the art of weaving to the molecular level in order to achieve unique and valuable mechanical properties from the nanostructure. Weaving is uncommon in nanotechnology, but the team innovated ways to weave organic threads that could build complex 2D and 3D structures.

As mentioned earlier, COFs and its cousin MOFs (metal organic frameworks) are porous, are made from lightweight materials and have large internal surface areas that can absorb and store enormous quantities of the target molecule. COFs and MOFs are stitched into diamond like crystals to reduce carbon dioxide into carbon monoxide, which serves as a primary building block for a wide range of chemical products including fuels, pharmaceuticals and plastics.

In their research the COF’s are synthesized by imine condensation reactions of aldehyde functionalized copper(I)-bisphenanthroline tetra fluoroborate, Cu(PDB)2(BF4) and benzidine (BZ). The copper centers are geometrically independent of the weaving within the COF structure and serve as a mould. Using X-ray and electron diffraction techniques, the copper could be removed and the structure could be restored to COF-505, which is the imine based framework.

Yaghi claimed that the reversible property could be used to design molecular cloths and the air refresher technology could also be upgraded. The current system has already initialized its next steps towards practical implantation, and we might expect such technology to make a transition into the market in the next few years. This research was primarily supported by BASF (Germany) and the King Abdulaziz City for Science and Technology (KACST).

Read the full downloadable #-Link-Snipped-#(supported by Yaghi Lab).

Source: <a href="https://vcresearch.berkeley.edu/news/weaving-new-story-cofs-and-mofs" target="_blank" rel="nofollow noopener noreferrer">Weaving a New Story for COFS and MOFs | Research UC Berkeley</a> | #-Link-Snipped-#

Covalent Organic Framework is an organic structure developed in the crystalline framework, having strong covalent bonds between its sub building blocks. Having light elements interweaved, the structure shows storage properties of gasses such as Methane, Hydrogen, Carbon and features useful optical properties. As an application, COFs have been used to capture carbon dioxide and#-Link-Snipped-#

2D diagram of COF

As mentioned earlier, COFs and its cousin MOFs (metal organic frameworks) are porous, are made from lightweight materials and have large internal surface areas that can absorb and store enormous quantities of the target molecule. COFs and MOFs are stitched into diamond like crystals to reduce carbon dioxide into carbon monoxide, which serves as a primary building block for a wide range of chemical products including fuels, pharmaceuticals and plastics.

In their research the COF’s are synthesized by imine condensation reactions of aldehyde functionalized copper(I)-bisphenanthroline tetra fluoroborate, Cu(PDB)2(BF4) and benzidine (BZ). The copper centers are geometrically independent of the weaving within the COF structure and serve as a mould. Using X-ray and electron diffraction techniques, the copper could be removed and the structure could be restored to COF-505, which is the imine based framework.

Yaghi claimed that the reversible property could be used to design molecular cloths and the air refresher technology could also be upgraded. The current system has already initialized its next steps towards practical implantation, and we might expect such technology to make a transition into the market in the next few years. This research was primarily supported by BASF (Germany) and the King Abdulaziz City for Science and Technology (KACST).

Read the full downloadable #-Link-Snipped-#(supported by Yaghi Lab).

Source: <a href="https://vcresearch.berkeley.edu/news/weaving-new-story-cofs-and-mofs" target="_blank" rel="nofollow noopener noreferrer">Weaving a New Story for COFS and MOFs | Research UC Berkeley</a> | #-Link-Snipped-#

0