Researchers devise an elastic touch sensitive fiber which is tailor made for use in electronics

From the multitude of senses, humans possess one named touch or tactioception that helps us "feel" the physical reality. As technology evolved with time, the electronic gadgets received an upgraded nourishment to mobile devices, supported peripherals and beyond. Following the course of improvement, a research team from the North Carolina State University has engineered an elastic, touch-sensitive fiber which is born with a quality to be interfaced with electronic modules.

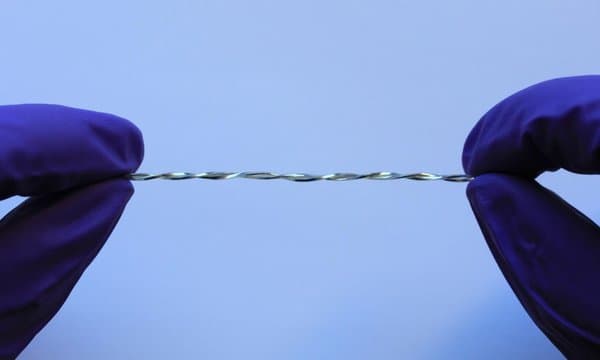

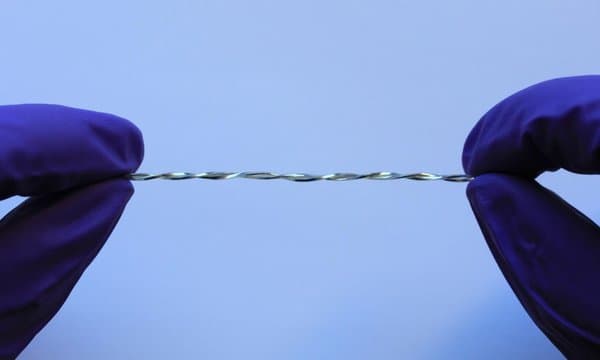

Professor of chemical and biomolecular engineering at NC State, Michael Dickey has implied that the newly devised string is sensitive enough to not only detect touch but also twisting or strain that makes it the key component to embed electronics on a platform. The soft, nanometer sized polymer made tubular threads are just slightly thicker than a human hair. The polymer-filled threads can further be divided into three strands among which the first one is completely packed with eutectic gallium and indium (EGaIn), the second one is two-third and the third one is one-third filled using the same polymer component.

Further, the strands are then twisted together, keeping a deep similarity with twisted pair wiring system. The microscopic objects actually work like the capacitive touchscreens, where a direction from the user is followed as you finger touch the touchscreen. Interestingly once you touch the responsive touch screen the capacitance between your finger and the touchscreen (possibly a glass coated with indium tin oxide) changes which drives the device to synchronize with your commands.

Touch Sensitive Fiber

Similarly, when you touch the polymer wire, the conductor-insulator-conductor configuration takes a shape and the capacitance between your finger and EGaIn, kept under the insulated fiber coating, changes. If you further rub the wire, or stroke your finger over the fiber, the capacitance will vary depending on the presence of EGaIn in the cable. Suggesting the theory, the group said this particular arrangement will bear different electrical signals.

The team also developed a sensor out of two fibers, spiraled together. The tighter the arrangement the closer the polymer gets to each other, putting an effect on its capacitance. The team members mentioned that their project is the best for determining how quickly something revolves, putting the instrument inside a torsion sensors. Plus, having been made out of elastic fiber, the spiral turns could be increased to 100 times more in number. The complete work has been recently published in the Advanced Functional Materials journal.

Watch out the touch sensor devised by NCSU researchers:

Source: #-Link-Snipped-#

Professor of chemical and biomolecular engineering at NC State, Michael Dickey has implied that the newly devised string is sensitive enough to not only detect touch but also twisting or strain that makes it the key component to embed electronics on a platform. The soft, nanometer sized polymer made tubular threads are just slightly thicker than a human hair. The polymer-filled threads can further be divided into three strands among which the first one is completely packed with eutectic gallium and indium (EGaIn), the second one is two-third and the third one is one-third filled using the same polymer component.

Further, the strands are then twisted together, keeping a deep similarity with twisted pair wiring system. The microscopic objects actually work like the capacitive touchscreens, where a direction from the user is followed as you finger touch the touchscreen. Interestingly once you touch the responsive touch screen the capacitance between your finger and the touchscreen (possibly a glass coated with indium tin oxide) changes which drives the device to synchronize with your commands.

Touch Sensitive Fiber

Similarly, when you touch the polymer wire, the conductor-insulator-conductor configuration takes a shape and the capacitance between your finger and EGaIn, kept under the insulated fiber coating, changes. If you further rub the wire, or stroke your finger over the fiber, the capacitance will vary depending on the presence of EGaIn in the cable. Suggesting the theory, the group said this particular arrangement will bear different electrical signals.

The team also developed a sensor out of two fibers, spiraled together. The tighter the arrangement the closer the polymer gets to each other, putting an effect on its capacitance. The team members mentioned that their project is the best for determining how quickly something revolves, putting the instrument inside a torsion sensors. Plus, having been made out of elastic fiber, the spiral turns could be increased to 100 times more in number. The complete work has been recently published in the Advanced Functional Materials journal.

Watch out the touch sensor devised by NCSU researchers:

0