Plastic bender

Introduction:

I'm currently working on a project about food growing. In order to do it I need a bench to bend plastic (acrylic) easly to make the main structure. The goal is to bend plastic and also being able to make precise curvy bends.

I have seen some DIY project that propose to heat up a wire of nichrome from a batteryy/variac and other..

Here are some examples :

- <a href="https://www.wa4dsy.com/robot/hot-wire-plastic-bender" target="_blank" rel="nofollow noopener noreferrer">www.wa4dsy.com</a>

- #-Link-Snipped-#

- <a href="https://www.youtube.com/watch?v=wVEf7PfuKxo" target="_blank" rel="nofollow noopener noreferrer">- YouTube</a>

Project:

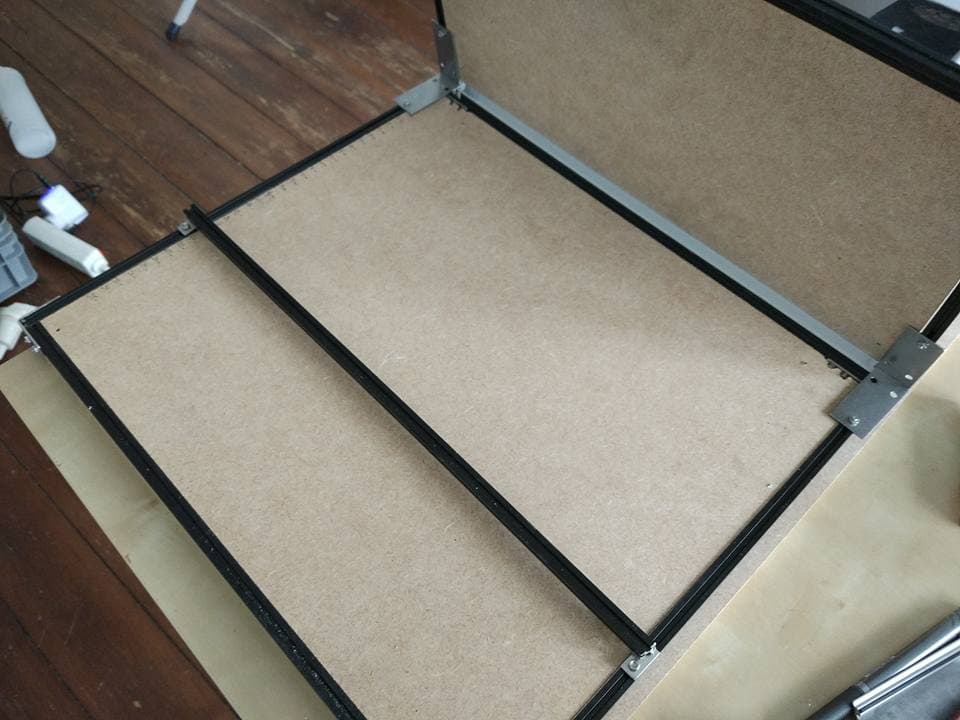

Here are some picture of where the project is a this moment.

Picture 1: whole structure made of agglomerated wood, aluminium beams and small other pieces.

Picture 2: show hoz the structure is going to bend the plastic

Picture 3: it's the area where the wire is going to stand and heat up the plastic

Next:

I'm novice in electronics and I need to find the best and safest solution to heat up the wire.

Some possibilities:

- Use a Variac : expensive but easly customable, electricity could be dangerous

- Use a 12V battery 7mAh: less expensive but how long os the battery gonna last? Less dangerous with electricity as I would be playing with 12V

- Use a voltage variator: look also dangerous because I would be playing with hight voltage. But cheap

(<a href="https://www.befr.ebay.be/itm/REGOLATORE-DI-VELOCITA-SCR-3500W-220V-PER-MOTORI-AC-LAMPADE-DIMMER-TENSIONE-TEMP-/222057172918?hash=item33b3a38fb6%3Ag%3AkMwAAOSwMORW6-KO" target="_blank" rel="nofollow noopener noreferrer">REGOLATORE DI VELOCITA SCR 3500W 220V PER MOTORI AC LAMPADE DIMMER TENSIONE TEMP en vente | eBay</a>)

What would you do?

What nichrome would you use?

Thanks in advance for your answer, I'm gonna give you the result as soon as possible!