New Non-destructive Industrial Testing Technique Devised

A group of researchers from the National Institute of Standards and Technology (NIST) has recently engineered an accelerated non-destructive testing method to analyse a series of materials in a real world situation. The design sheds much needed light on the roll-to-roll measurement technique, the system of processing instruments or objects using a conveyor belt.

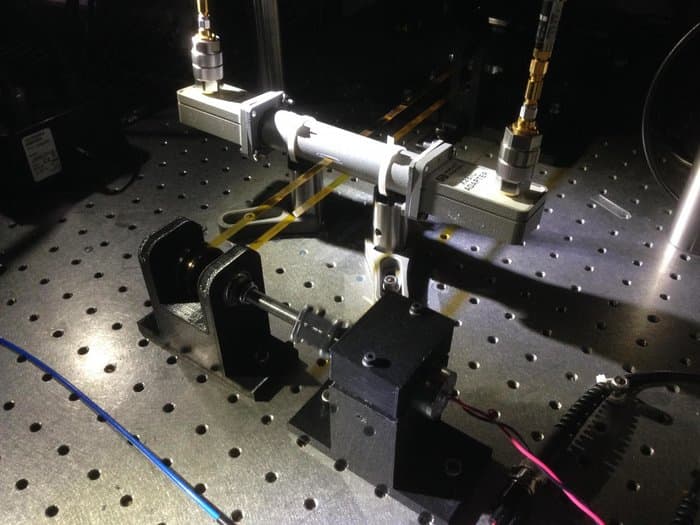

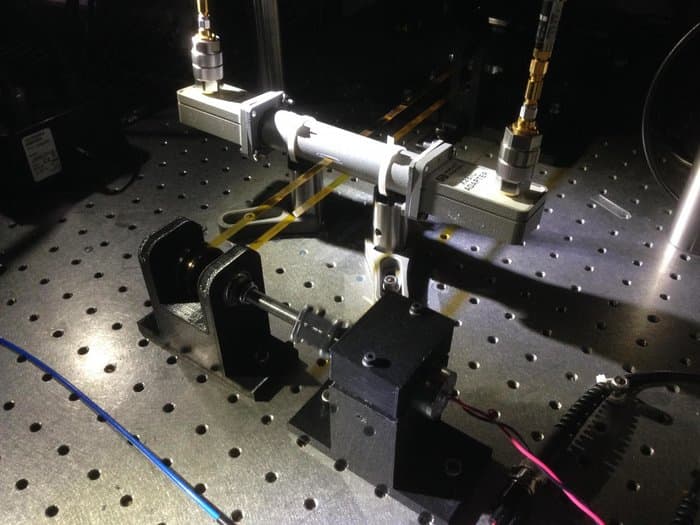

For any new material to make a transition from the laboratory to the industry, it must undergo some specific tests. Current methods of quality control tests include invasive processes such as cutting, scratching, threading, all of which may hamper the test subject. To implement a non-contact process, physicists Nathan Orloff, Christian Long and Jan Obrzut from the aforementioned institute, passed a material through a specifically manufactured microwave cavity.

Measurements of electrical properties of a plastic tape

When the material is passed through the channel, the existing resonant frequency changes corresponding to the object's size, electrical resistance and dielectric constant. The team has also built an electric circuit to monitor the changes. Additionally, the integrated system can also be used to study electrical properties of materials having faint characteristics and a known length.

Orloff claimed that their research product offers various advantages over a thin-film manufacturer. With the help of the latest discovery, the user might be able to completely confirm the product’s reliability and usability. The complete research was titled as “Noncontact conductivity and dielectric measurement for high throughput roll-to-roll Nano manufacturing†and published in the Scientific Reports journal.

Source: #-Link-Snipped-#

For any new material to make a transition from the laboratory to the industry, it must undergo some specific tests. Current methods of quality control tests include invasive processes such as cutting, scratching, threading, all of which may hamper the test subject. To implement a non-contact process, physicists Nathan Orloff, Christian Long and Jan Obrzut from the aforementioned institute, passed a material through a specifically manufactured microwave cavity.

Measurements of electrical properties of a plastic tape

Orloff claimed that their research product offers various advantages over a thin-film manufacturer. With the help of the latest discovery, the user might be able to completely confirm the product’s reliability and usability. The complete research was titled as “Noncontact conductivity and dielectric measurement for high throughput roll-to-roll Nano manufacturing†and published in the Scientific Reports journal.

Source: #-Link-Snipped-#

0