Microprocessors Can Be Kept Cool Using Carbon Nanotubes - Berkeley Lab Research

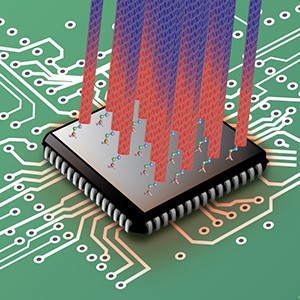

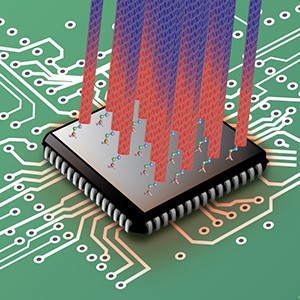

Microprocessor chips manufacturing companies across the world face the issue of overheating that leads to performance diminishing. The power in a microprocessor is dissipated as heat energy. As the semiconductor industry is getting busy in fitting more and more transistors onto a single chip, the depletion region gets smaller, and current leaks through the transistor even when it is off. Due to this leakage, the chips produce more heat, and wastes additional power. Heat can also cause materials to expand, which can alter the electrical characteristics of the tiny transistors and wires. As a solution to this problem, the current systems employ a mechanism that involves transferring the heat from the chip onto the circuit board, where it can then be dispersed using fans or other techniques. But with the advance technology at hand, researchers with the U.S. Department of Energy (DOE)’s Lawrence Berkeley National Laboratory (Berkeley Lab) have developed a “process friendly†technique that would enable the cooling of microprocessor chips through carbon nanotubes.

The research began when Intel came to the Molecular Foundry (a DOE nanoscience center hosted by Berkeley Lab) wanting to improve the performance of carbon nanotubes in devices. Interestingly, the thermal conductivity of carbon nanotubes is more than that of diamond or any other natural material but because carbon nanotubes are so chemically stable, their chemical interactions with most other materials are relatively weak, which makes for high thermal interface resistance. Sumanjeet Kaur, lead author of the Nature Communications paper and an expert on carbon nanotubes, with assistance from co-author and Molecular Foundry chemist Brett Helms, used reactive molecules to bridge the carbon nanotube/metal interface—aminopropyl-trialkoxy-silane (APS) for oxide-forming metals, and cysteamine for noble metals.

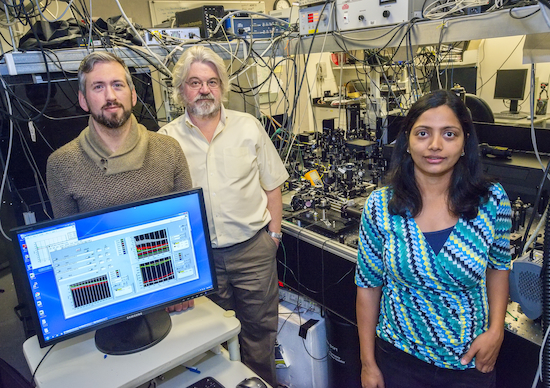

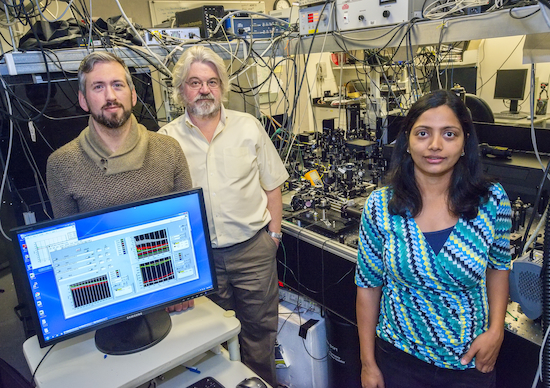

From left, Brett Helms, Frank Ogletree and Sumanjeet Kaur at the Molecular Foundry used organic molecules to form strong covalent bonds between carbon nanotubes and metal surfaces, improving by six-fold the flow of heat from the metal to the carbon nanotubes. (Photo by Roy Kaltschmidt)

“You can think of interface resistance in steady-state heat flow as being an extra amount of distance the heat has to flow through the material,†Kaur says. Using carbon nanotubes in their technique, they have been able to decrease the interface resistance so that the extra distance is around seven microns (instead of 40) at each interface.

The approach used by Ogletree, Kaur and their colleagues isn't yet full-proof. It has been able to significantly strengthened the contact between a metal and individual carbon nanotubes within an array, but most nanotubes within the array may still fail to connect with the metal. The Berkeley team is now working on a way to improve the density between carbon nanotube metal contacts. Other than microprocessors, the single and multi-layer graphene devices which face the same cooling issues, could also find their savior in carbon nanotubes.

What do you think about the concept and idea behind the use of carbon nanotubes for microprocessor cooling? There is still a long way to go before we see them become available in our laptops and tablets. Share your thoughts with us in comments below.

Source: #-Link-Snipped-#

The research began when Intel came to the Molecular Foundry (a DOE nanoscience center hosted by Berkeley Lab) wanting to improve the performance of carbon nanotubes in devices. Interestingly, the thermal conductivity of carbon nanotubes is more than that of diamond or any other natural material but because carbon nanotubes are so chemically stable, their chemical interactions with most other materials are relatively weak, which makes for high thermal interface resistance. Sumanjeet Kaur, lead author of the Nature Communications paper and an expert on carbon nanotubes, with assistance from co-author and Molecular Foundry chemist Brett Helms, used reactive molecules to bridge the carbon nanotube/metal interface—aminopropyl-trialkoxy-silane (APS) for oxide-forming metals, and cysteamine for noble metals.

From left, Brett Helms, Frank Ogletree and Sumanjeet Kaur at the Molecular Foundry used organic molecules to form strong covalent bonds between carbon nanotubes and metal surfaces, improving by six-fold the flow of heat from the metal to the carbon nanotubes. (Photo by Roy Kaltschmidt)

The approach used by Ogletree, Kaur and their colleagues isn't yet full-proof. It has been able to significantly strengthened the contact between a metal and individual carbon nanotubes within an array, but most nanotubes within the array may still fail to connect with the metal. The Berkeley team is now working on a way to improve the density between carbon nanotube metal contacts. Other than microprocessors, the single and multi-layer graphene devices which face the same cooling issues, could also find their savior in carbon nanotubes.

What do you think about the concept and idea behind the use of carbon nanotubes for microprocessor cooling? There is still a long way to go before we see them become available in our laptops and tablets. Share your thoughts with us in comments below.

Source: #-Link-Snipped-#

0