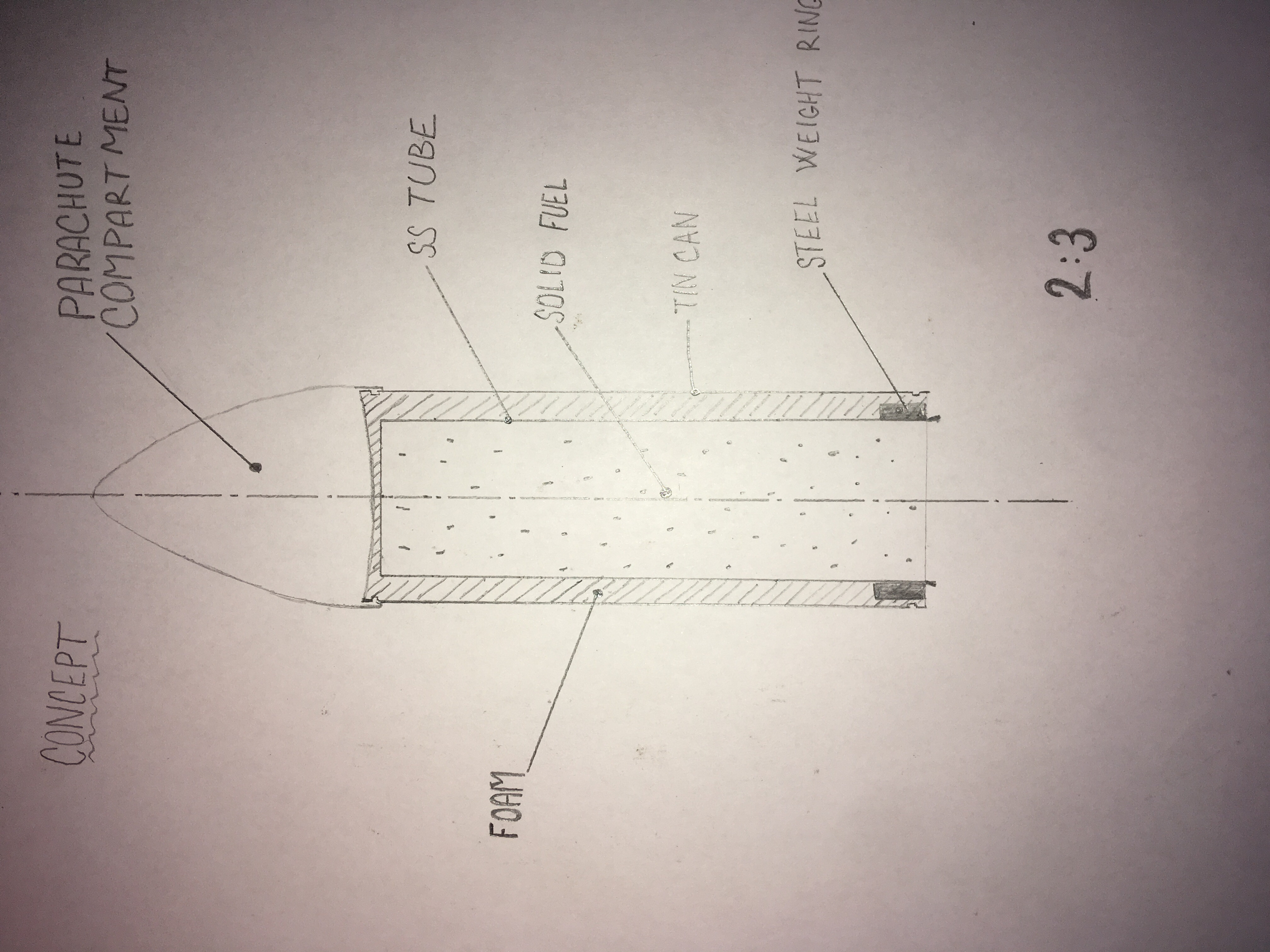

Light but tight foam for rocket?

Hi fellow engineers, I m looking for a foam to fill space between outer wall and inner wall of a homemade rocket. I need something that will not damage or deform by aerodynamic stress on the rocket. The outer wall is made by “red b*ll” can so I need a foam to support its shape. Thanks