How to remove water from liquid digestate?

I am working on a project to dry liquid digestates (residue from the fermentation process of biogas plants). The aim of the project is to reduce the volume of the liquid digestate, in order to cut the transport and storage costs for the farmers. This volume reduction is achieved by evaporation of water from the digestate.

The liquid digestate has a dry matter (DM) content of about 3%. The digestate is primarily made up of animal manure and maize silage. It is a non-newtonian fluid having a viscosity of 4 - 15 mPa-s. It exhibits a shear thinning behaviour, where the viscosity decreases with shear rate.

A drum dryer is used, which runs continuously (24x7) with an automatic setting. The dryer makes use of the heat from the combined heat and power (CHP) unit. The task is to remove/evaporate 1 liter of water for every 1 kW of heat supplied from the CHP unit.

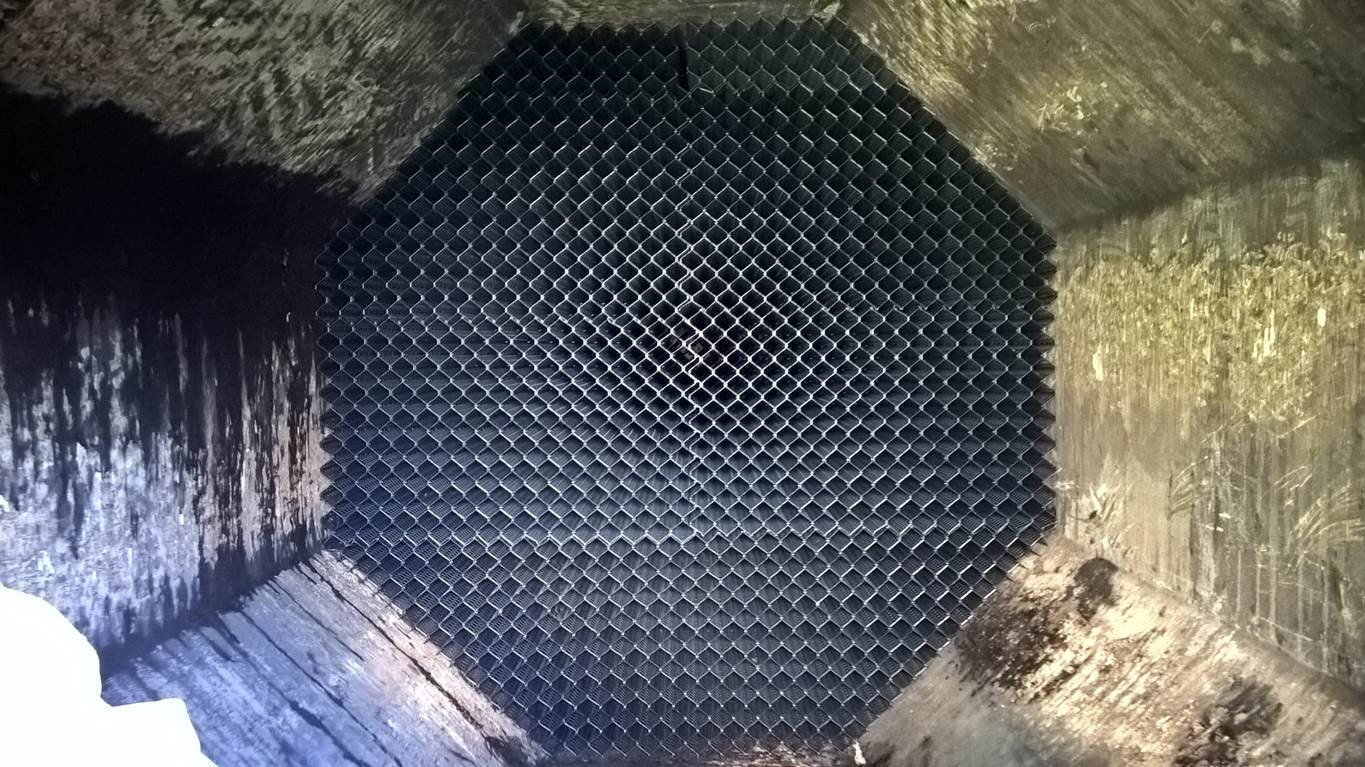

The liquid digestate after the separation process is fed into the drum dryer at a temperature of 40°C. Hot air with a temperature of 70°C is blown into the drum to dry the digestate. The drum is packed with cooling tower fills (see image below) in order to facilitate evaporation by increasing the heat transfer surface area between digestate and air.

The problem is that the tiny fibres from the liquid digestate, inspite of pre-separation process, get deposited on the cooling tower fills and the clog the air flow (see image below). Thereby the whole functioning of the dryer is affected.

These tiny fibres are suspended and float in the liquid digestate, as it is difficult to filter them out. Hence, I would like to know, if heating the liquid digestate helps? What happens to these tiny floating fibres in the liquid, when the temperature is raised from 40°C to 60°C? Definitely the viscosity of the liquid would decrease, but does it affect these tiny fibres?

How can this fibre deposition and clogging of flow be avioded? Are there better methods to increase the heat transfer area, other than cooling tower fills? Any new suggestions are welcome.

Thank you.