Desert Beetles Inspire New Frost Repelling Technology

The Boreyko research team from the department of Engineering Science and Mechanics at Virginia Tech has developed frost-controlling chemical micropatterns on a silicon surface having a size of a centimetre. Scientists used the photolithography technology to design chemical hydrophilic patterns over a hydrophobic silicon wafer leading to prevention of water condensation, an indirect way of forming frosts.

Dr. Jonathan Boreyko, team leader of the research group explained that the idea behind their research was motivated by Namib Beetles (Stenocara gracilipes), native to the coastal desert of Africa, Namib. Though they live in a hot desert, they potentially survive by storing water on their bumpy back surface. The primary research was carried out on a centimetre order wafer, which could later be replaced by a larger fused (hydrophobic and hydrophilic) structure.

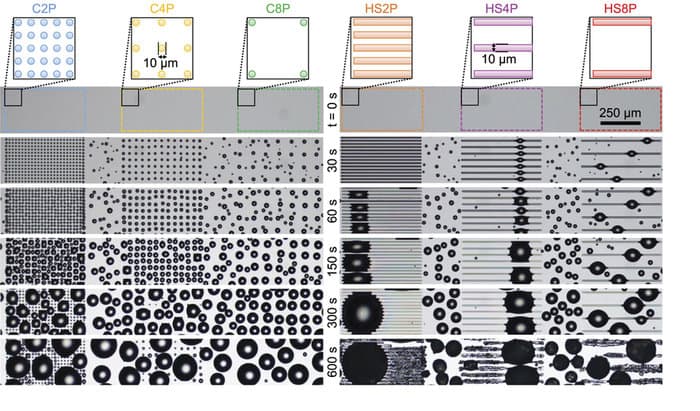

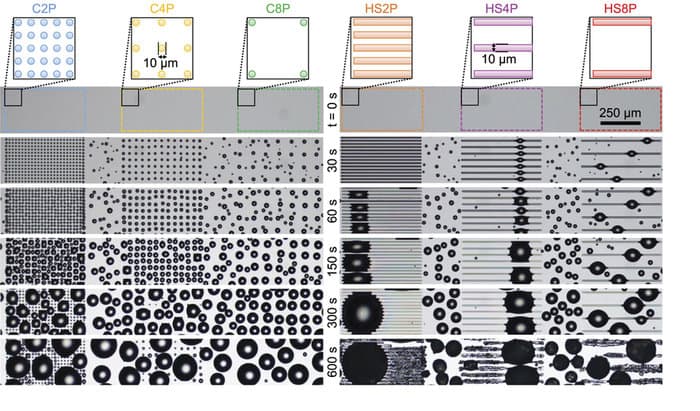

The colored shapes in the schematics represent the hydrophilic features while the white background is hydrophobic

In the experimental setup, the hydrophilic material was made of Silicon oxide and the hydrophobic areas consisted of a silane monolayer. Before merging the two different materials, both were washed with the Oxygen plasma to restore their completely characteristics. The patterns developed were invisible if seen through an optical microscope, and were only revealed via condensation which takes place in the hydrophobic monolayer. The condensation was grown by cooling the substrate to either 5 degrees Celsius or -10-degree Celsius, resulting in controllable spacing of the condensation and finally preventing the process.

Ice serves as a humidity sink due to its lower vapour pressure as compared to liquid water. Ice harvests water from dew drops and initially only a single drop freezes, thereby starting a chain reaction in frost deposition over a layer. The pressure difference causes the ice to spread, but with the newly designed beetle-inspired non-linear system, the same phenomenon would create a dry zone instead of frost.

The team claimed that the engineered product would provide permanent solutions to prevent frost on airplane parts, condenser coils and windshields. The research was jointly supported by the Centre for Nanophase Materials Sciences and the Department of Biomedical Engineering and Mechanics at Virginia Tech. The research was reported in the 'Nature materials' journal.

Watch the speed controlling of frost growth of frost across surfaces here:

Source: #-Link-Snipped-#

Dr. Jonathan Boreyko, team leader of the research group explained that the idea behind their research was motivated by Namib Beetles (Stenocara gracilipes), native to the coastal desert of Africa, Namib. Though they live in a hot desert, they potentially survive by storing water on their bumpy back surface. The primary research was carried out on a centimetre order wafer, which could later be replaced by a larger fused (hydrophobic and hydrophilic) structure.

The colored shapes in the schematics represent the hydrophilic features while the white background is hydrophobic

In the experimental setup, the hydrophilic material was made of Silicon oxide and the hydrophobic areas consisted of a silane monolayer. Before merging the two different materials, both were washed with the Oxygen plasma to restore their completely characteristics. The patterns developed were invisible if seen through an optical microscope, and were only revealed via condensation which takes place in the hydrophobic monolayer. The condensation was grown by cooling the substrate to either 5 degrees Celsius or -10-degree Celsius, resulting in controllable spacing of the condensation and finally preventing the process.

Ice serves as a humidity sink due to its lower vapour pressure as compared to liquid water. Ice harvests water from dew drops and initially only a single drop freezes, thereby starting a chain reaction in frost deposition over a layer. The pressure difference causes the ice to spread, but with the newly designed beetle-inspired non-linear system, the same phenomenon would create a dry zone instead of frost.

The team claimed that the engineered product would provide permanent solutions to prevent frost on airplane parts, condenser coils and windshields. The research was jointly supported by the Centre for Nanophase Materials Sciences and the Department of Biomedical Engineering and Mechanics at Virginia Tech. The research was reported in the 'Nature materials' journal.

Watch the speed controlling of frost growth of frost across surfaces here:

Source: #-Link-Snipped-#

0