Pneumatic cylinder Construction: Design

Hello,

I don't have much knowledge in mechanical design or pneumatic systems.

For my project, I want to create a Pneumatic cylinder, The purpose is, Inside it will will contain a Nylon piston, and one end will be filled with clay. Cylinder will be closed from either side using end caps, which also has Push-in connectors(1/4" BSP). Compressed Air from a cylinder(Max. pressure of Cylinder 10 Bar) will be given to Piston side through a Non return valve and a Regulator. Which will push the Clay out through other end. It is for my Clay printer. Hope anyone here have some background with these kind of system

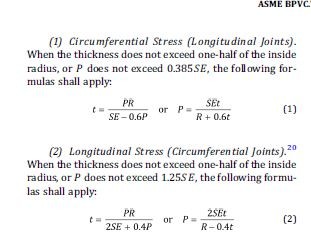

What should be the Wall thickness of Cylinder? It should safely handle Maximum pressure that might arise.

I have already provided a Safety valve calibrated at 6 Bar in my prototype that I made from a GI water Pipe, which has thickness of 3.85 mm. Is there any way the pressure inside the tank could reach a pressure higher than the maximum pressure Compressor can deliver (Compressor is rated for 10 Bar, with cutoff at 8 Bar)

I'm thinking about making the cylinder using a 100 x 5.75 mm Aluminium Pipe and End caps from Aluminum Rods with wall thickness of 10 mm. Would this be enough?

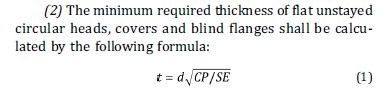

Should I give more thickness for End caps than cylinder?

How to find the maximum pressure rating of the cylinder if material, Wall thickness and diameter are known?

I asked this in another forum and one gay gave me two pictures

can anyone explain this to, what each parameter units are etc