Help or advice on how to manufacture this product?

I'm(22m) am a 3rd year product design engineering student and we've been tasked with bringing a previous designed concept to the point that you have a complete idea of what it would be produced (basically how will it be manufactured, to what scale, who is sold to, how is it packaged etc). I'm getting held back by the maufacture

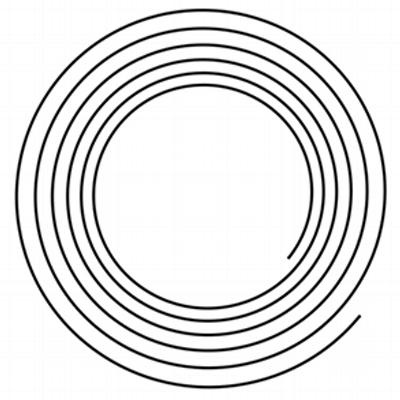

The photo is my previously designed concept: the idea is you drop metal ball down the slide (a conical spiral) and the ball is collected in the tray at the bottom. Its designed to be able to be placed in the corner of the average office desk (e.g. its a office desk marble run).

My question is:Â what process will I use to manufacture the spiral slide and what can I make it out of?

Ideally, I'd like to have it to have a fairly clean aesthetic look (e.g not just bend some PVC pipe) as its going to marketed as a nice ornament to have on your desk. I'm not too worried about the supports or the base but creating the conical spiral slide shape is giving me a lot of grief. I know I can 3D print the shape (as I have a model) but I don't think this is the most cost effective strategy and I have to produce a document of how much it will cost etc. Should I adapt the design slightly to make it easier to make? If so how should I do this?

Can I CNC mill the shape out of wood or metal? Can I injection mould it out of plastic? Can I use a set up like this (Â <a href="https://www.youtube.com/watch?v=yigRgG_NIyU" target="_blank" rel="nofollow noopener noreferrer">tube bending - YouTube</a> ) and just using half a pipe? Could I set up a wood turning rig?