New Self Adaptive Biomimetic Material; Stays Tough, Heals Itself

Researchers at Rice University, have developed a material called SAC (self adaptive composite) obtained by mixing two polymers and a solvent that evaporates when heated leaving a gooey forms of spheres. The material behaves as a sponge returning to its normal original state after compression. Rice materials scientists Pulickel Ajayan and Jun Lou who led the study opined that the biocompatible material might be useful in the field of tissue-engineering or in light-weight defect-tolerant structural applications.

With the ease of fabrication, tunability and great scale-up potential it sure offers multiple distinct advantages and has a long way to go. The research appeared in the American Chemical Society journal ACS Applied Materials and Interfaces.

Source: #-Link-Snipped-#

The solid-liquid self adaptive composite uses Poly (dimethylsiloxane) (PDMS) and Poly (vinylidene fluoride) (PVDF) as active constituents. PDMS coats the entire surface of the material while PVDF encapsulates liquid. The liquid enhances visco-elasticity of the material; stabilized within a continuous solid network percolating throughout the structure. The structure with its pores, solid, liquid interface form a complex hierarchical structure that provides the mechanical robustness, multi-functionality and structural adaptability under external forces.

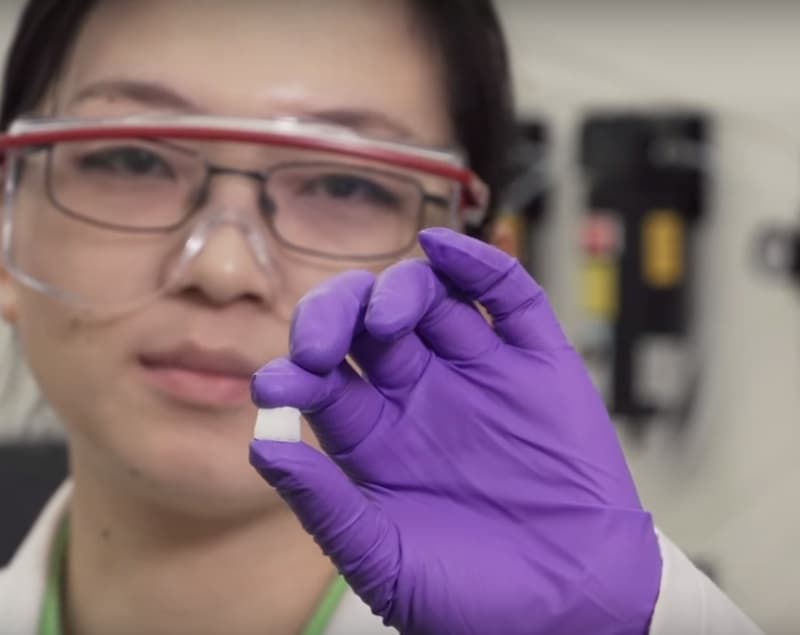

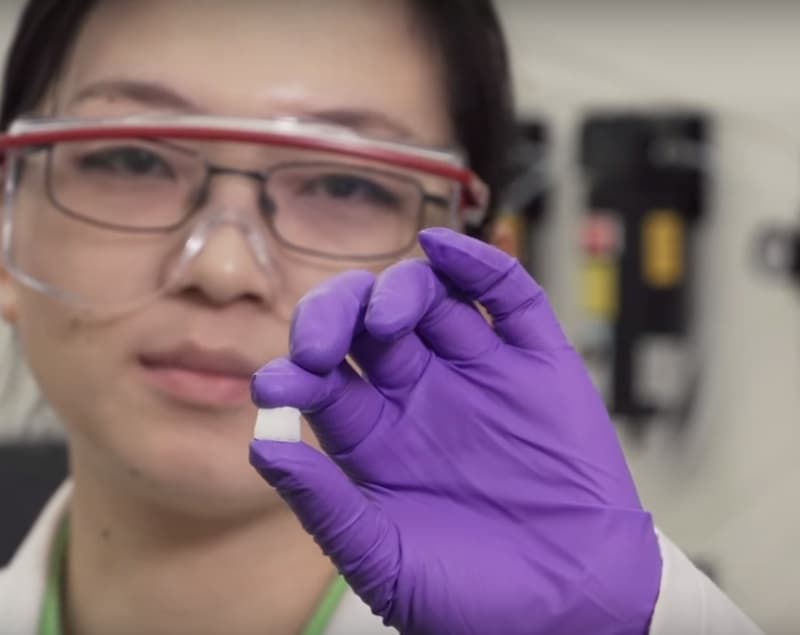

The sample resembles a sugar cube that can be compressed much and has no evidence of it containing any liquid when externally examined. The polymer components are powder and viscous liquid to begin with, however with addition of solvent and regulated heating, it stabilizes into solid formations with reconfigurable internal structure.

What distinguishes the current material from other self-healing materials on block is its flexibility. Its liquid is stable and doesn’t flow in everywhere unlike earlier materials which behaved so. A maximum of 683 percent increase in the material’s storage modulus – a size-independent parameter used to characterize self-stiffening behavior, was reported in tests, which is much greater than other composite materials.

The sample resembles a sugar cube that can be compressed much and has no evidence of it containing any liquid when externally examined. The polymer components are powder and viscous liquid to begin with, however with addition of solvent and regulated heating, it stabilizes into solid formations with reconfigurable internal structure.

What distinguishes the current material from other self-healing materials on block is its flexibility. Its liquid is stable and doesn’t flow in everywhere unlike earlier materials which behaved so. A maximum of 683 percent increase in the material’s storage modulus – a size-independent parameter used to characterize self-stiffening behavior, was reported in tests, which is much greater than other composite materials.

With the ease of fabrication, tunability and great scale-up potential it sure offers multiple distinct advantages and has a long way to go. The research appeared in the American Chemical Society journal ACS Applied Materials and Interfaces.

Source: #-Link-Snipped-#

0