3D Printing Breakthrough Builds High Temperature, High Strength Ceramic Components

Researchers at HRL laboratories, LLC, have announced a significant leap in the world of 3-D printing - the ability to print ceramics. The word “ceramic†is derived from the Greek word ceramos, i.e., “from potteryâ€. This inorganic substance has traversed a long route, and from an object of pottery, it is now an output of the 3-D printer.

The list of materials that can be 3-D printed has always been considered exhaustible, and ceramic is undoubtedly an important addition to it. Courtesy a materials science trick, the vastly used solid substance could very well now be the outcome of a hassle-free production process.

The extremely high melting point of many ceramics poses significant challenges in obtaining them via additive manufacturing, which as a process, is generally suitable for polymers and other metals. Naturally, the researchers had to find a way out - they printed out 3-D designs of so-called preceramic polymers, which could later be converted to ceramic upon heating. The preceramic resin, they demonstrated, is compatible with a popular additive manufacturing process called stereolithography, wherein a laser is used to solidify a liquid polymer in a layer-upon-layer format. Also discovered was that going beyond conventional stereolithography by using ultraviolet light could produce the ceramic output at a rate 1000 times the rate of the usual process.

The researchers also demonstrated how the ceramic so produced was as good as we know it to be. HRL Sensors and Materials Laboratory Senior Scientist Dr. Tobias Schaedler mentions that the printed resin is high in strength, full in density and can withstand temperatures as high as 1700°C. The obtained strength, in fact, is ten times the strength of similar materials.

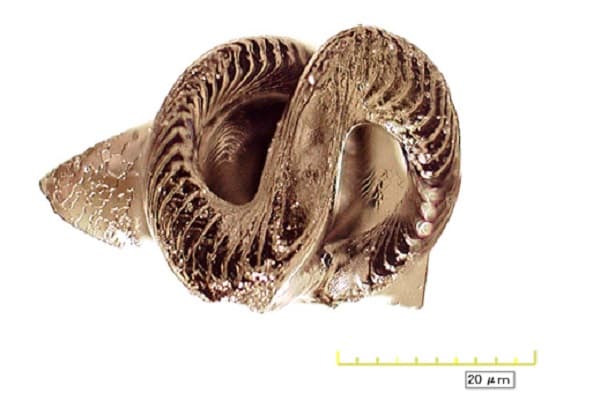

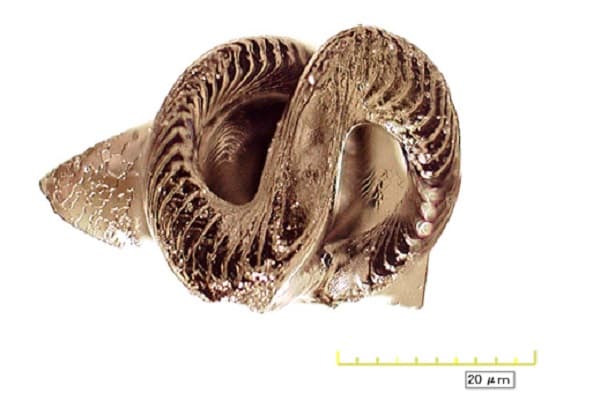

The process has helped overcome a number of limitations that are often associated with ceramics, which includes amongst others, their inability to be casted or machined. This renders ceramics, although wide in applications and excellent in properties, difficult to produce. Here, however, the preceramic is very conveniently pyrolized to the resultant with uniform shrinkage and virtually no porosity.

The ceramics- silicon oxycarbide microlattices and honeycomb cellular materials- could be used in extended applications, Schaedler adds. Fabrications ranging from large components in jet engines to hypersonic vehicles, to intricate parts in microchemical systems and electronic packaging could be easily developed.

Source: #-Link-Snipped-#

The list of materials that can be 3-D printed has always been considered exhaustible, and ceramic is undoubtedly an important addition to it. Courtesy a materials science trick, the vastly used solid substance could very well now be the outcome of a hassle-free production process.

The extremely high melting point of many ceramics poses significant challenges in obtaining them via additive manufacturing, which as a process, is generally suitable for polymers and other metals. Naturally, the researchers had to find a way out - they printed out 3-D designs of so-called preceramic polymers, which could later be converted to ceramic upon heating. The preceramic resin, they demonstrated, is compatible with a popular additive manufacturing process called stereolithography, wherein a laser is used to solidify a liquid polymer in a layer-upon-layer format. Also discovered was that going beyond conventional stereolithography by using ultraviolet light could produce the ceramic output at a rate 1000 times the rate of the usual process.

The researchers also demonstrated how the ceramic so produced was as good as we know it to be. HRL Sensors and Materials Laboratory Senior Scientist Dr. Tobias Schaedler mentions that the printed resin is high in strength, full in density and can withstand temperatures as high as 1700°C. The obtained strength, in fact, is ten times the strength of similar materials.

The process has helped overcome a number of limitations that are often associated with ceramics, which includes amongst others, their inability to be casted or machined. This renders ceramics, although wide in applications and excellent in properties, difficult to produce. Here, however, the preceramic is very conveniently pyrolized to the resultant with uniform shrinkage and virtually no porosity.

The ceramics- silicon oxycarbide microlattices and honeycomb cellular materials- could be used in extended applications, Schaedler adds. Fabrications ranging from large components in jet engines to hypersonic vehicles, to intricate parts in microchemical systems and electronic packaging could be easily developed.

Source: #-Link-Snipped-#

0