Researchers Develop Micro-sized, Liquid-Metal Particles For Heat-Free Soldering

Scientists at Iowa State University in USA have successfully developed micro-scale, liquid-metal particles which can be put to use for heat-free soldering, fabricating, repairing and processing of metals - all at room temperature. The project was initially undertaken as a search for a way to stop liquid metal from returning to a solid – even below the metal’s melting point. Something known as ‘undercooling’ in the field of metal structure and processing.

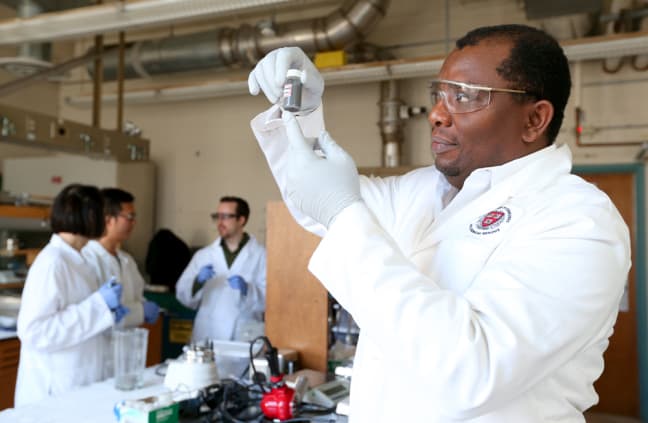

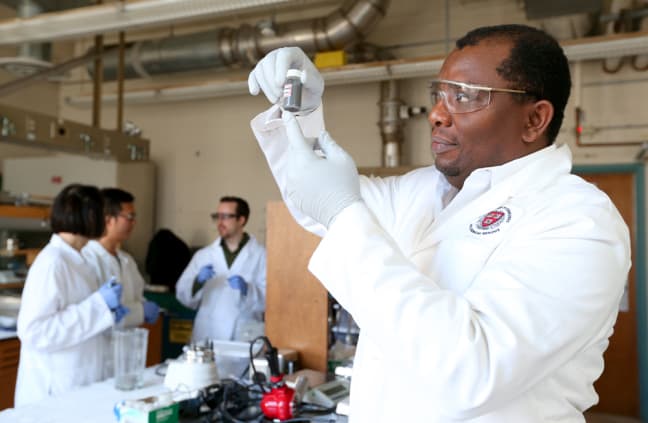

Martin Thuo holds a vial of the liquid-metal particles produced by his research group

Martin Thou, an assistant professor at Iowa State University and his group created liquid-metal particles containing Field’s metal (an alloy of bismuth, indium and tin) and particles containing an alloy of bismuth and tin. The particles are 10 micrometers in diameter, about the size of a red blood cell. These were exposed to oxygen after which an oxidation layer was allowed to cover them, essentially creating a capsule containing the liquid metal. The layer is then polished until it is thin and smooth.

The tiny droplets of liquid metal are covered with a thin, uniform coating, so as to form stable particles of undercooled liquid metal. The researchers wanted to essentially build a system where the metals don’t turn into solids.

These liquid metal particles could have significant implications for manufacturing. It could aid in healing of damaged surfaces and soldering/joining of metals at room temperature without requiring high-tech instrumentation, complex material preparation or a high-temperature process. In the research scientists also note to have experimented with a new technique that uses a high-speed rotary tool to sheer liquid metal into droplets within an acidic liquid.

It had always been a challenge to produce large and stable quantities of undercooled metals however with this breakthrough, practical, sustainable and inexpensive solution to the problem seems plausible.

The research was published in #-Link-Snipped-#

Source: Iowa State engineers develop micro-sized, liquid-metal particles for heat-free soldering • News Service • Iowa State University

Martin Thuo holds a vial of the liquid-metal particles produced by his research group

The tiny droplets of liquid metal are covered with a thin, uniform coating, so as to form stable particles of undercooled liquid metal. The researchers wanted to essentially build a system where the metals don’t turn into solids.

These liquid metal particles could have significant implications for manufacturing. It could aid in healing of damaged surfaces and soldering/joining of metals at room temperature without requiring high-tech instrumentation, complex material preparation or a high-temperature process. In the research scientists also note to have experimented with a new technique that uses a high-speed rotary tool to sheer liquid metal into droplets within an acidic liquid.

It had always been a challenge to produce large and stable quantities of undercooled metals however with this breakthrough, practical, sustainable and inexpensive solution to the problem seems plausible.

The research was published in #-Link-Snipped-#

Source: Iowa State engineers develop micro-sized, liquid-metal particles for heat-free soldering • News Service • Iowa State University

Replies

You are reading an archived discussion.

Related Posts

I am a first year student at the University of Lyon, France and I am required to interview an engineer about their job. This interview is part of a professional...

Catsharks taxonomically belong to one of the largest families, Scyliorhinidae and possess a unique pair of cat-like eyes and body-patterns, where some of them are commonly dubbed as Chain Catsharks....

Looking for a large-aperture lens, vast zoom range an efficient image sensor in your camera? Sony's new Cyber-Shot series RX10 III might just be the right device for you. Featuring...

After graduating as a computer science engineer in the year 2006, Amar Gautam started working as a software engineer at KPIT, Pune. Within 4 years he became a Technical Leader...

Motorola finally launched the much awaited Moto 360 Sport in India for a price tag of ₹19,999 through FlipKart. This smartwatch is a sports variant of the recently launched generation...