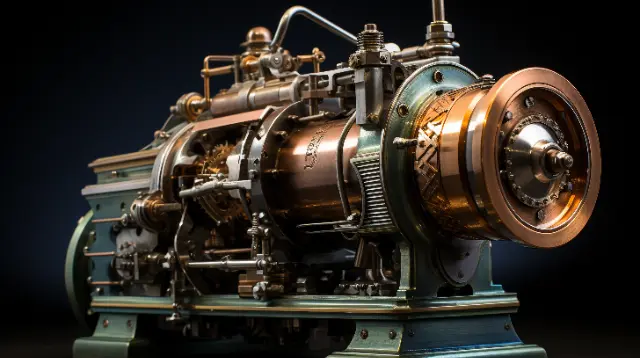

6 Stroke Engine: Working Principle, Firing Order, Pros and Cons

Let’s discuss six stroke engines, their working principle and firing order, its advantages and disadvantages. Later on, we’ll also compare it with 2-stroke and 4-stroke engines. Shall we start?

Six Stroke Engine Working Principle and Firing Order

The 6-stroke engine operates on an extended cycle of the traditional 4-stroke engine, incorporating two additional strokes - water injection and steam exhaust.

Intake Stroke: The first stroke involves drawing an air and fuel mixture into the cylinder.

Compression Stroke: During the second stroke, the air-fuel mixture is compressed.

Combustion Stroke: The compressed mixture is then ignited, forcing the piston down.

Exhaust Stroke: The fourth stroke expels the burnt gases.

Water Injection Stroke: This is the first additional stroke unique to the 6-stroke engine, where water is injected into the hot cylinder.

Steam Exhaust Stroke: Finally, the injected water turns into steam due to the residual heat in the cylinder, forcing the piston down again, and the steam is then expelled.

The firing order of the 6-stroke engine depends on the number of cylinders and the configuration of the engine, much like the 4-stroke engine.

However, with the additional two strokes, each cylinder will complete a cycle in three revolutions of the crankshaft instead of two.

The specific firing order will vary depending on the design and application of the engine.

Benefits of the 6-Stroke Engine

Enhanced Efficiency: The added two strokes help extract more work from the same amount of fuel, thereby improving the engine's thermal efficiency.

Lower Emissions: The water injection stroke significantly reduces the temperature of the combustion chamber, minimizing the formation of nitrogen oxides (NOx), a harmful emission.

Internal Cooling: The water injection and steam exhaust strokes cool the engine internally, reducing the necessity for an extensive cooling system.

Better Fuel Economy: The extra power stroke contributes to getting more work done with the same amount of fuel, resulting in improved fuel economy.

Drawbacks of the 6-Stroke Engine

Increased Complexity: The inclusion of two more strokes adds to the complexity of the engine design and operation.

Water Injection System: The requirement of a water injection system increases the engine's weight and cost.

Comparison with 4-Stroke and 2-Stroke Engines

Efficiency: The 6-stroke engine surpasses both the 4-stroke and 2-stroke engines in efficiency by extracting more work from the same amount of fuel.

Emissions: The 6-stroke engine generates lower emissions compared to the 4-stroke and 2-stroke engines due to the water injection stroke.

Cooling: The 6-stroke engine demands less external cooling compared to the 4-stroke and 2-stroke engines as it is cooled internally by the water injection and steam exhaust strokes.

Complexity: The 6-stroke engine is more complex than the 4-stroke and 2-stroke engines due to the additional strokes and systems required.

Practical Applications of the 6-Stroke Engine

Although the 6-stroke engine is still under development, its potential applications are broad-ranging.

Automobiles: The 6-stroke engine, with its increased efficiency and lower emissions, could be a valuable option for powering automobiles.

Power Generation: The superior fuel economy of the 6-stroke engine makes it an appealing choice for power generation applications.

Marine Applications: The internal cooling feature of the 6-stroke engine makes it suitable for marine applications where cooling water is readily available.

The 6-stroke engine, with its advantages of enhanced efficiency, reduced emissions, and internal cooling, offers a promising alternative to conventional 4-stroke and 2-stroke engines.

However, challenges such as increased complexity and the need for a water injection system must be addressed for it to become a viable option for mainstream applications.

Despite these challenges, as the demand for cleaner and more efficient engines grows, the 6-stroke engine represents a step forward.

I really hope that this small guide helps you understand six stroke engines a bit in more detail. If you have questions, ask them below. I’ll try my best to answer.

Replies

-

crookI can help. Tell me what are you looking for? Are you trying out modification in six stroke engine? Or you are designing one on your own?

crookI can help. Tell me what are you looking for? Are you trying out modification in six stroke engine? Or you are designing one on your own?

Also, why should you put your email address in the post? What purpose does it solve?

Crook -

Kaustubh KatdareI'm afraid this might not be very useful, but thought of sharing it. Follow the link for an interesting article on Six Stroke Engine-

Kaustubh KatdareI'm afraid this might not be very useful, but thought of sharing it. Follow the link for an interesting article on Six Stroke Engine-

#-Link-Snipped-#

-The Big K- -

kavyaHAY CROOK 😒

kavyaHAY CROOK 😒

I AM DESIGNING ONE OF MY OWN ALONG WITH MY TEAM N FOR GOD SAKE PLZ DON'T DISCOURAGE ME N UR OUESTION IS RIGHT WHAT PURPOSE MY EMAIL WILL SOLVE .LET ME TELL U YAAR ITS A SECRET MATTER MAY BE SOMEONE AFRAID OF ANSWERING IN PUBLIC.......................UNDERSTANDING U I THINK ................................................SO HELP ME.....................THANKLS FOR UR SUGGESTION...............................HAY ANY BODY IF U HAVE SOME MATTER FOR SIX STROKE ENGINE ...................EMAIL ME AT..........................

THANKS

:sshhh:

KAVYA -

Kaustubh KatdareGood to see that Kavya & her team is designing a six stroke engine. It would certainly help if Kavya & her team shares their progress, problems & difficulties as well as knowledge gained in this project. I think its still not clear what help Kavya & her team needs.

Kaustubh KatdareGood to see that Kavya & her team is designing a six stroke engine. It would certainly help if Kavya & her team shares their progress, problems & difficulties as well as knowledge gained in this project. I think its still not clear what help Kavya & her team needs.

I think we have discussed following points lot of times and they are part of our Common Sense Guide (available on main page) -

1. CEans *must* use 'English' while posting on CE forums. Avoid using 'Hindi' or any other language while posting. We are read by people from all over the world.

2. Avoid using long trail of dots between words in your posts.

3. There is no point in asking help through email. This destroyes the basic purpose of forums and knowledge should be open to all.

4. Avoid ALL CAPS! This is called as 'shouting'. Use "*" to highlight word/sentence if required.

5. Be nice to everyone. You never know who the person offering free help to you is.

-The Big K- -

kavyahello

kavyahello

thanks reminding me of what to do n how to do......

i need help regarding its cooling system.&stroke workings. -

crookFirst of all, the purpose behind invention of six-stroke engine: Reduced fuel consumption.

crookFirst of all, the purpose behind invention of six-stroke engine: Reduced fuel consumption.

In Cower's six stroke engine, a jet of water is introduced in the heated chamber. Water gets converted into steam and expands resulting into another power stroke.

It should be noted that the engine does not need separate cooling mechanism. The water jet added to the cylinder carries away the extra heat. An interesting thing about this engine is that you can touch while its running, therefore you need not design a cooling mechanism. The engine will however run only for 30 to 35 minutes. -

Kaustubh KatdareThat was quite informative. Its interesting to know that the six stroke engine does not need extra cooling mechanism.

Kaustubh KatdareThat was quite informative. Its interesting to know that the six stroke engine does not need extra cooling mechanism.

I've no clue if six stroke engines are already into production. Can anyone update this thread?

-The Big K- -

desijays

desijays

if the water take away the heat along with it and if the engine does not require any cooling mechanism then why is it that it can run for only 30 to 35 minutes... just curious?crookThe engine will however run only for 30 to 35 minutes.

i don't think we need any more engines that use any form of fossil fuel. when the world needs to prepare itself to a gasoline free environment, i think this will only hinder the progress, if it is in production.The_Big_KI've no clue if six stroke engines are already into production. Can anyone update this thread?

i don't see vehicles using fossil fuels to power themselves in the future. electricity is the answer that will solve many problem.....

middle east oil dependency

reduction in green house gas emissions

reduction in production costs ( electric cars tend to have a very less number of moving parts )

to name a few. -

rosh009no!desijays!u have got it wrong.electricity is not the answer to exhausting fossil fuels.because 1.its storage is a big problem,2.the recharging takes a long time, and the list goes on.

rosh009no!desijays!u have got it wrong.electricity is not the answer to exhausting fossil fuels.because 1.its storage is a big problem,2.the recharging takes a long time, and the list goes on.

but the answer to the near exhausting fossil fuels is the BIO-FUEL.ie.the fuel derived/extracted from plants/tree's fruits.

one major advantage of this is that it is inexhaustible.and the other major advantage is that it is ENVIRONMENT FRIENDLY!

the six stroke engine seems quite interesting and would like to know more about it!

and kavya go ahead with your project!all the best! -

desijays

desijays

no mate. I'm afraid it is you who is wrong. Electricity is the future. And your claims that storage is a huge problem and that it takes a long time to recharge are not entirely true.rosh009no!desijays!u have got it wrong.electricity is not the answer to exhausting fossil fuels.because 1.its storage is a big problem,2.the recharging takes a long time

I'm not sure if you have heard of the Tesla Roadster. Here is the URL. check it out. Its already in production. None of that hybrid crap. As they say on the website it is 100% electricity.

#-Link-Snipped-#

You can charge it over night. Complete charge in about 3.5 hours. Its a bit costly. But initially were'nt all things costly. Thats the part that needs working.

I won't eliminate BIO-fuel completely. May be it will complement the electricity driven economy. But i'll be hard pressed to find anyone who will say that it will replace electricity completely. -

rosh009ok!i understand it!but the fact is that no one wants to stay at a recharging station for 3.5 hours when they are on a long journey!

rosh009ok!i understand it!but the fact is that no one wants to stay at a recharging station for 3.5 hours when they are on a long journey! -

desijays

desijays

dear friend this is just the beginning. when the wright brothers flew their plane for the first time, it merely lasted 27 or so odd seconds.rosh009ok!i understand it!but the fact is that no one wants to stay at a recharging station for 3.5 hours when they are on a long journey!

there is no telling why 3.5 hours wouldn't be reduced to 5 minutes. besides the car was designed to be recharged at a normal power outlet found in a common house.

and why do you make the assumption that there will ever be recharging stations. may be they will never exist cos they were never necessary....... unlike typical gas stations today. -

Kaustubh Katdare:sshhh: Ssshh! No fight! 😁

Kaustubh Katdare:sshhh: Ssshh! No fight! 😁

Let us restrict this discussion to six stroke engines. Feel free to start new threads for new discussions.

Kavya, what is the update on your project? We would like to know.

-The Big K- -

kavyathanks friends

kavyathanks friends

till where the project matters ,till the date it is in its early stage n unfortunately our exams have came in between so we have to postpone it for some days but friends keep on discussing it because it may be possible that we may get any thread from discussion.n i will inform u all our current status after some weeks.

so for the time being i am busy with my exams. so keep it up ... -

Kaustubh KatdareKavya,

Kaustubh KatdareKavya,

Will it be possible for you to put the pictures of your six stroke engine on CrazyEngineers?

Also it would be great if you could share your learnings with other CEans so that it will be helpful to anyone who's willing to work on Six Stroke Engine.

-The Big K- -

kavyaM BACK

kavyaM BACK

HERE M PUTTING SOME QUESTIONS ANSWER FOR HELP

*HOW I CAN CONTROL THE INJECTOR PUMP TIMING?????????????

* HOW I CAN INJECT TWO DIFFERENT FUELS AT THE TWO DIFFERENT TIMES IN THE CYLINDER??????????

*ANY BODY ABOUT DUEL FUEL INJECTOR?????????????

EVERY ONE IS INVITED

😒 😡 😁 :smile: -

rosh009kavyaM BACK

rosh009kavyaM BACK

HERE M PUTTING SOME QUESTIONS ANSWER FOR HELP

*HOW I CAN CONTROL THE INJECTOR PUMP TIMING?????????????

* HOW I CAN INJECT TWO DIFFERENT FUELS AT THE TWO DIFFERENT TIMES IN THE CYLINDER??????????

*ANY BODY ABOUT DUEL FUEL INJECTOR?????????????

EVERY ONE IS INVITED

😒 😡 😁 :smile:

1.control of injector pump isn't going to be a problem because it will be handled by the electronic chip.

2.here u cannot refer water as an fuel.it is considerd only as a power enhancing liquid. and it cannot be injected through the same injector used for injection of the fuel.a reconstruction will be required at the head of the engine with an addition of one more water injector.

3.and i doubt a duel fuel injector can be used here.

because the injector used for fuel if used for water also may invite some friction problems.

and one more thing kaavya,can i know which city ru from,because in india a group of four students from trivandrum have already worked on this and currently some students of my college are also working on it. -

kavyam

kavyam

from rohtak 😔 😛 😉 n i don,t know what they have done but wt we think is m telling to u infact the making of a six stroke is not a problem but making it more useful is a problem ........n let ne tell u the 2nd fuel is infact controversial n we can use water or may be any fuel which can react with gases or carbon......if u have any information on it then tell me rather guide me....its m.d.u. ,rtk😒 :sshhh: -

shashidamdharThe_Big_K:sshhh: Ssshh! No fight! 😁

shashidamdharThe_Big_K:sshhh: Ssshh! No fight! 😁

Kavya, what is the update on your project? I would like to know.

-The Big K-[

Success is not the key to happiness. Happiness is the key to success. If you love what you are doing, you will be successful. -

crookshashidamdhar

crookshashidamdhar

What is this post about? 😒 Can someone update this thread with more information?The_Big_K:sshhh: Ssshh! No fight! 😁

Kavya, what is the update on your project? I would like to know.

-The Big K-[

Success is not the key to happiness. Happiness is the key to success. If you love what you are doing, you will be successful. -

kilaruhey i am new............

kilaruhey i am new............

can you pls tell me the six strokes ............i mean what happens in each stroke -

Kaustubh KatdareThe_Big_KI'm afraid this might not be very useful, but thought of sharing it. Follow the link for an interesting article on Six Stroke Engine-

Kaustubh KatdareThe_Big_KI'm afraid this might not be very useful, but thought of sharing it. Follow the link for an interesting article on Six Stroke Engine-

#-Link-Snipped-#

-The Big K-

Did you check out earlier posts in this thread? There's already a link that talks about each stroke in 6 stroke engine.kilaruhey i am new............

can you pls tell me the six strokes ............i mean what happens in each stroke

-The Big K-

PS: New Members - Go through CE Common Sense Guide on front page as well as Lectures 1,2,3 & 4 in our newbie training center. -

jalalrokhsatshare idea

jalalrokhsatshare idea

😁 Hi every body

we are 3 student in that work on this project(design six stroke engine)

plz help me to find some paper about it

and we can share our research about it with ur group?

thanks

God bless u .;-) -

btsbhtry this website and you will get what you are in search off....

btsbhtry this website and you will get what you are in search off....

#-Link-Snipped-#

kavyam

from rohtak 😔 😛 😉 n i don,t know what they have done but wt we think is m telling to u infact the making of a six stroke is not a problem but making it more useful is a problem ........n let ne tell u the 2nd fuel is infact controversial n we can use water or may be any fuel which can react with gases or carbon......if u have any information on it then tell me rather guide me....its m.d.u. ,rtk😒 :sshhh: -

TheBugInYouKOOL GUYZ.....

TheBugInYouKOOL GUYZ.....

HERE HERE, LET ME KNOW U WHAT ACTUALLY IT MATTERS. IN A TYPICAL 4-STROKE AS ALL OF US KNOW, A SUCTION-COMPRESSION-POWER-EXHAUST....

BUT IN 6 STROKE IT CONTINUES..

A SUCTION OF MIXTURE-COMPRESSION-POWER-EXHAUST (RESTRICTED)- AGAIN SUCTION OF UNBURNT/PARTIALLY BURNT EXHAUST-POWER.

THIS IS THE ACTUAL MERE PROCESS HAPPENS IN A TYPICAL 6-STROKE. YOU CAN CONVERT ANY EXISTING 4-STROKE ENGINE TO A 6-STROKE AS ALL U NEED TO ADD IS A SIMPLE EXHAUST SUCTION MECHANISM AND AN EXTRA SPARK PLUG EVENT.

KOOL YOU MAY TAKE ANY EXISTING (IF AND ONLY IF ITS WORKING) 4-STROKE HONDA ENGINE AND CARRY YOUR PROJECT.

ADVANTAGES:

THE MAIN ADVANTAGE ID THE REDUCTION OF FUEL CONSUMPTION AND REDUCTION OF POLLUTION

LET ME REMIND U THE DISADVANTAGES:

UNEVEN PRODUCTION OF TORQUE AND FLUCTATIONS IN FLYWHEEL CAUSES UNDAMPABLE JERKS IN THE ENGINE AT EITHER LOW/HIGH SPEEDS. THIS IS THE REASON WHY COMMERCIALLY THEY ARE VERY LESS IN PREFERENCE AND USAGE.

ANYWAY NICE DISCUSSION. I HAD THIS PROJECT IN MY B.E. Ist YEAR. KOOL IF ANY MORE STUFF NEEDED LEAVE U R QUESTION OR RESPONSE HERE...

OH I AM THE-BUG-IN-YOU -

sourabh011hi friends,

sourabh011hi friends,

i am working on the six stroke engine concept and i m having a 96 cc passion engine.i want to know that how will the secondry fuel be sprayed in the cylider just after the exhaust stroke instead of the intake of air fuel mixture??

can we do it by changing the shape of the cam to the inlet valve?? -

TheBugInYouSourabh

TheBugInYouSourabh

Its no secondary fuel. all you need is a to way in ad a i=one way out mechanism coupled with camshaft. As soon a the completion of power stroke, the exhaust stroke follows. but collecting those exhaust gases and sending hm in to the cylinder and making them burnt.the two way in and out, what i mentioned is a tap like valve which may allow fresh petrol to spray in orthe exhaust gases , controlled by the cam timing, and then letting it into the cylinder.

But... this is once upon-a-time project. in hose days the exhaust gas used to contain more and more carbon and unburnt fuel particles. so it would be good to use the unburnt fuel again and burn them But now-a-days, the engines are designed in a sophisticated manner, not leaving a single unburnt particle out. So no more use to convert your passion 4-stroke to 6-stroke. -

rishisolankihey the bug in you

rishisolankihey the bug in you

you are saying that we need only to induce the exhaust gases again in the cylinder

but in other six stroke engines we have to inject distilled water which forms steam which expands manier times to give the power stroke

so finally do tell us u r discussing about power stroke by only exhaust gases or by distilled water?? -

rosh009hey the bug in you,

rosh009hey the bug in you,

the idea in discussion here is not of the concept to use the un-burnt/half-burnt exhaust gases inturn utilise the fuel to max. in delivering greater efficiency.

instead it is a concept where in the intense heat generated during the combustion process is utilised to generate additional two strokes using distilled water.

and the reason why the exhaust gases aren't re-used is becuase of the fact that one never knows[or atleast till date no one has designed a system which predicts] how much percent of a fuel gets burnt completely or how much gets half-burnt.

Due to this "inconsistentcy" factor of exhaust gases,

its not worth a re-use to produce additional two strokes.

and there are other ways to TAP the intense heat generated during combustion like using THERMO-ELECTRIC materials as cover to these engines and inturn tap heat. although the idea is a practical one, its not economical , for the thermo-electric materials are too costly to be manufactured in mass.

its true that thermo-electric materials is one of the future materials which is going to play a major role in energy conservation and usage.

but its just a matter of time before someone discovers a cheap/easily affordable thermo-electric material similar to how the SILICON was discovered for the electronics industry!!! -

satheesh27887Hi Kavya....

satheesh27887Hi Kavya....

I'm Doing Final Year Mechanical....

Just Now Only I Read About Your Project....

I'm Ready To Help You.....

Can I Know For Wat Purpose Your Are Going For Secondary Fuels....

R U Going To Increase The Engine Performance Or Something Else..... -

balajmdhello

balajmdhello

i like to help you in this we are doing third year in mechanical engineering. i think we can help you in your project. -

Kaustubh Katdare

Kaustubh Katdare

Hello balajmd,balajmdhello

i like to help you in this we are doing third year in mechanical engineering. i think we can help you in your project.

Good to see you on board. How about starting a new discussion about your project in our Mechanical & Civil Engineering section?

I believe we very much need some inputs on six stroke engines related discussions from engineers who've worked on it. -

geococeohello i am new to this forum and came here to learn and share about six strokes.

geococeohello i am new to this forum and came here to learn and share about six strokes.

i have been thinking about timing and injection on an old one cylinder diesel i would like to convert to six strk. either the cams can be modified which is tricky as hell or the cam can be de-actuated for two strokes which is also tricky. if i was building motor from scratch i would make a larger cam with two nodes 120 degrees apart and the rest blank(to keep the valves closed for the sixth stroke) injection should be easy just look at old mechanical steam injectors from bygone steam era and rig it up mechanically to the drive belt, of course you could probly find some new fancy ones that are electronic but i prefer mechanical, just my taste.

also, i like the idea of not exhausting the gas from the fossil stroke and reusing it in combination with steam so that the more fuel wasted in this stroke the more efficient the next will be, in turn balancing efficiency

lubrication is a problem above my brain as of now -

gaganjot singhthe main quest here is how will the timing work for 6 strokes

gaganjot singhthe main quest here is how will the timing work for 6 strokes -

raj87verma88

raj87verma88

You have already asked this question in another thread. Give people some time to respond.gaganjot singhthe main quest here is how will the timing work for 6 strokes -

anand87thanks a lot to all the great mehanical engineers here for sharing such valuable info

anand87thanks a lot to all the great mehanical engineers here for sharing such valuable info -

adi.apr15

adi.apr15

Friends even i have been working on Six Stroke Engine and am having it as a project in my final year..most of the things are fine and in place except these questions:rosh009

1.control of injector pump isn't going to be a problem because it will be handled by the electronic chip.

2.here u cannot refer water as an fuel.it is considerd only as a power enhancing liquid. and it cannot be injected through the same injector used for injection of the fuel.a reconstruction will be required at the head of the engine with an addition of one more water injector.

3.and i doubt a duel fuel injector can be used here.

because the injector used for fuel if used for water also may invite some friction problems.

and one more thing kaavya,can i know which city ru from,because in india a group of four students from trivandrum have already worked on this and currently some students of my college are also working on it.

1) what kind of injectors can we use to inject water coz diesel injectors can't be used to help the purpose..they get jammed and rusted when water runs through them and need continuous lubrication..this happens coz the clearance between the injector plunger and injector cylndr is very less!!

2)How much time does it takes for a given quantity of water to convert into steam..(i hve been trying a lot of formulas but am unable to find 1-thr seems to be no relationship lyk that)

3)How much pressure will the produced steam create on the head of the piston coz that should be sufficient to make the engine work for those two xtra strokes..

PLZ help!!! -

zheeveiif the engine is made from cast iron then water + heated iron = rust ??

zheeveiif the engine is made from cast iron then water + heated iron = rust ?? -

sree the marinerhi kavya,

sree the marinerhi kavya,

iam appreciate u for preparing a nic project. I hav a great doubt in 6 stroke engine that wat material u used for preparing this type of engine becoz while the water get enters it suddenly converted to steam that means a thermoshock wil occur and wat u do for it. -

mechkyIn the beginning of this thread, on page 1, a something is written about 6 stroke engine :

mechkyIn the beginning of this thread, on page 1, a something is written about 6 stroke engine :

'The engine will however run only for 30 to 35 minutes.'

Can any one comment that why is it so? -

mechky

mechky

No it is not that simple. The cylinder block is usually made of grey cast iron but the cylindrical space in which piston reciprocates is formed by cylinder liners which are made of alloyed cast iron and are relatively less prone to corrosion.zheeveiif the engine is made from cast iron then water + heated iron = rust ?? -

CE DesignerThe diesel engine was invented by Rudolf Diesel because he thought that the gasoline engine was not very efficient. In his time, late 1870's, it was found that only about 10% of the gasoline would be used to move the vehicle while the rest was lost as useless heat. This brilliant idea of using water to capture that heat to produce an extra power stroke is really and truly a 'stroke' of genius.

CE DesignerThe diesel engine was invented by Rudolf Diesel because he thought that the gasoline engine was not very efficient. In his time, late 1870's, it was found that only about 10% of the gasoline would be used to move the vehicle while the rest was lost as useless heat. This brilliant idea of using water to capture that heat to produce an extra power stroke is really and truly a 'stroke' of genius.

Even if there is a possibility of rust engineering can solve that easily. We have so many materials and alloys at our disposal, i can see this definitely being the future of the ICE. -

saptm6 stroke engine is a great idea to manufacture.Many companies are trying to manufacturing six stroke engine.The prototype is already made and about the second fuel,water is used.Since,according to the Boyle's Law when water is converted into steam it increases it volume by 22.4L so that it will increase the volume in the cylinder and cool the exhaust easily.The main reason of making six stroke engine is when the exhaust gases thrown out of the cylinder, experimentally it is determined that 33% of wastes gases can again used as the fuel for the cylinder. Its a really good idea to have six stroke engine,in same air-fuel mixture we are getting half cycle more,so the efficiency increases.

saptm6 stroke engine is a great idea to manufacture.Many companies are trying to manufacturing six stroke engine.The prototype is already made and about the second fuel,water is used.Since,according to the Boyle's Law when water is converted into steam it increases it volume by 22.4L so that it will increase the volume in the cylinder and cool the exhaust easily.The main reason of making six stroke engine is when the exhaust gases thrown out of the cylinder, experimentally it is determined that 33% of wastes gases can again used as the fuel for the cylinder. Its a really good idea to have six stroke engine,in same air-fuel mixture we are getting half cycle more,so the efficiency increases.

and all the best for your project and if have any query feel free to ask. -

mechky

mechky

It seems you have worked on something like this. I have some queries on water injection.saptm6 stroke engine is a great idea to manufacture.Many companies are trying to manufacturing six stroke engine.The prototype is already made and about the second fuel,water is used.Since,according to the Boyle's Law when water is converted into steam it increases it volume by 22.4L so that it will increase the volume in the cylinder and cool the exhaust easily.The main reason of making six stroke engine is when the exhaust gases thrown out of the cylinder, experimentally it is determined that 33% of wastes gases can again used as the fuel for the cylinder. Its a really good idea to have six stroke engine,in same air-fuel mixture we are getting half cycle more,so the efficiency increases.

and all the best for your project and if have any query feel free to ask.

The only injectors available in India for direct injection into combustion chamber are diesel injectors(petrol injectors are port injectors). Now, two types of diesel injectors are there - mechanical and electronic. Mechanical injectors are not much efficient when used with water due to friction and lubrication issues. Also mechanical injectors require certain amount of pressure to build up before they open. Since diesel injectors are relatively high pressure injectors(400 bar and over), water injection in gasoline engine requires injection pressure to be only around 5 bar. More the pressure of injected water more is its boiling temperature. So, mechanical injectors are not a good option for water injection.

Whereas electronic injectors are solenoid operated which open on passage of current through the solenoid. So, according to this solenoid diesel injectors can be operated at practically any pressure as supplied by the pump. This gives electronic diesel injectors appropriate for water injection, neglecting friction and corrosion issues.

Please provide your views on this and correct me if I am wrong. -

saptmSee we can use any of the injector for the injection of water but as you said mechanical injectors are not so efficient,we can just use these injector in the small assembly connected to the cylinder.There are two ways of manufacturing six stroke engine. First,we can operate all six stroke in one cylinder.Secondly,we can operate compression one in one cylinder and compression two in the cylinder attachment.I think the second option is good because due to water we have to make the whole one big cylinder robust and free from cracks but by using second way we just have to make the attachment robust and we can use mechanical and solenoid injector and it will be bit less costly then the first one.And yes,solenoid injector is much efficient in most of the vehicle but now a days we are using ECU and artificial intelligence in the vehicles from which we can easily operate the injector and there is a less chance of wear and tear also.

saptmSee we can use any of the injector for the injection of water but as you said mechanical injectors are not so efficient,we can just use these injector in the small assembly connected to the cylinder.There are two ways of manufacturing six stroke engine. First,we can operate all six stroke in one cylinder.Secondly,we can operate compression one in one cylinder and compression two in the cylinder attachment.I think the second option is good because due to water we have to make the whole one big cylinder robust and free from cracks but by using second way we just have to make the attachment robust and we can use mechanical and solenoid injector and it will be bit less costly then the first one.And yes,solenoid injector is much efficient in most of the vehicle but now a days we are using ECU and artificial intelligence in the vehicles from which we can easily operate the injector and there is a less chance of wear and tear also. -

saptm

saptm

NewmechkyIt seems you have worked on something like this. I have some queries on water injection.

The only injectors available in India for direct injection into combustion chamber are diesel injectors(petrol injectors are port injectors). Now, two types of diesel injectors are there - mechanical and electronic. Mechanical injectors are not much efficient when used with water due to friction and lubrication issues. Also mechanical injectors require certain amount of pressure to build up before they open. Since diesel injectors are relatively high pressure injectors(400 bar and over), water injection in gasoline engine requires injection pressure to be only around 5 bar. More the pressure of injected water more is its boiling temperature. So, mechanical injectors are not a good option for water injection.

Whereas electronic injectors are solenoid operated which open on passage of current through the solenoid. So, according to this solenoid diesel injectors can be operated at practically any pressure as supplied by the pump. This gives electronic diesel injectors appropriate for water injection, neglecting friction and corrosion issues.

Please provide your views on this and correct me if I am wrong.

See we can use any of the injector for the injection of water but as you said mechanical injectors are not so efficient,we can just use these injector in the small assembly connected to the cylinder.There are two ways of manufacturing six stroke engine. First,we can operate all six stroke in one cylinder.Secondly,we can operate compression one in one cylinder and compression two in the cylinder attachment.I think the second option is good because due to water we have to make the whole one big cylinder robust and free from cracks but by using second way we just have to make the attachment robust and we can use mechanical and solenoid injector and it will be bit less costly then the first one.And yes,solenoid injector is much efficient in most of the vehicle but now a days we are using ECU and artificial intelligence in the vehicles from which we can easily operate the injector and there is a less chance of wear and tear also.

You are reading an archived discussion.