Trains In Netherlands Will Soon Be Equipped With Lasers To Clean Debris From Tracks

Every time you try to picture a European country in the autumn season images of yellow and orange coloured fallen leaves comes into mind. Those beautiful autumn leaves however pose a threat to trains. In wet winters, fallen leaves tend to stick to the tracks and once a train passes over them the heat generated by the friction of train wheels transforms them into a hard Teflon-like residue that sticks on the tracks and makes it difficult for trains to grip on them. According to Delft University of Technology Professor Rolf Dollevoet the leaves residue increase the braking distance to 800 meters which is twice normal value. The slippery track also manages to disrupt anti-collision systems on trains. Currently trains are employing tactics like shooting water or a mixture of gel and sand called Sandite on tracks to remove debris. These methods have two drawbacks. First they have to be constantly restocked on the train and secondly materials like sand and water can damage the track in the long run.

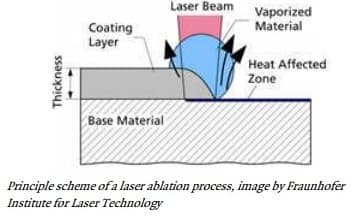

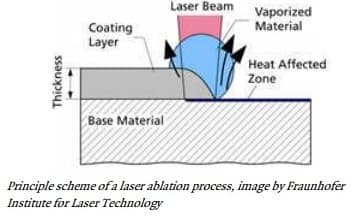

To address the aforementioned issue, Professor Rolf Dollevoet and Dirk Schipper have collaborated with Dutch railways to test the efficiency of a laser based system to get rid of leaves. The idea behind the Laser Railhead Cleaner (LRC) is to use a laser to heat organic material on the rails so that they rapidly expand and separate themselves from rails. Apart from removing rust, the track which is now warm will prevent leaves from sticking on to it. The LRC system which has been developed by Strukton Systems is able to clean 20mm of railhead on each side at speeds up to 80kmph. Details of the LRC system such as power and number of lasers remain unknown.

Sure the system sounds futuristic but it has its own pitfalls. First there is the question of accuracy. The LRC will work only when it is precisely aimed at the tracks and on a moving train it is quite difficult. All the vibrations generated by the train wheels and coaches will mess with the laser system. Strukton Rail, the developers of the project say that during such vibrations the lasers are programmed to switch themselves off but switching off a critical system in the journey defeats the purpose. Next we have the problem of speed; the lasers cannot work when the train is travelling at speeds over 50mph. This means that the system cannot be installed on high speed trains whose average speeds are over 150mph. The team of professors are expected to hand in their results within this month after which the railway company will decide on the future course of action.

To know more about the LRC you can read the #-Link-Snipped-# on the project followed by its coverage on #-Link-Snipped-# and #-Link-Snipped-#.

To address the aforementioned issue, Professor Rolf Dollevoet and Dirk Schipper have collaborated with Dutch railways to test the efficiency of a laser based system to get rid of leaves. The idea behind the Laser Railhead Cleaner (LRC) is to use a laser to heat organic material on the rails so that they rapidly expand and separate themselves from rails. Apart from removing rust, the track which is now warm will prevent leaves from sticking on to it. The LRC system which has been developed by Strukton Systems is able to clean 20mm of railhead on each side at speeds up to 80kmph. Details of the LRC system such as power and number of lasers remain unknown.

Sure the system sounds futuristic but it has its own pitfalls. First there is the question of accuracy. The LRC will work only when it is precisely aimed at the tracks and on a moving train it is quite difficult. All the vibrations generated by the train wheels and coaches will mess with the laser system. Strukton Rail, the developers of the project say that during such vibrations the lasers are programmed to switch themselves off but switching off a critical system in the journey defeats the purpose. Next we have the problem of speed; the lasers cannot work when the train is travelling at speeds over 50mph. This means that the system cannot be installed on high speed trains whose average speeds are over 150mph. The team of professors are expected to hand in their results within this month after which the railway company will decide on the future course of action.

To know more about the LRC you can read the #-Link-Snipped-# on the project followed by its coverage on #-Link-Snipped-# and #-Link-Snipped-#.

0