Torispherical dish end calculations.

Can Anyone give me the formula for calculating plate size needed to make the 10 % torispherical dish ends for a reactor?

Diameter of reactor is 3000 mm

Height of Reactor is 3500 mm

volume required is 25 m3

Shell Thickness is 10 mm

I Want to Know is what shall be the diameter of 12 mm circular plate required before it can be bent to form the dish ends?

Answer:

Torispherical dish ends, also known as torispherical domes, are used in a variety of pressure vessels, reactors and tanks.

The geometry of a torispherical head is more complex than a simple spherical or cylindrical shell.

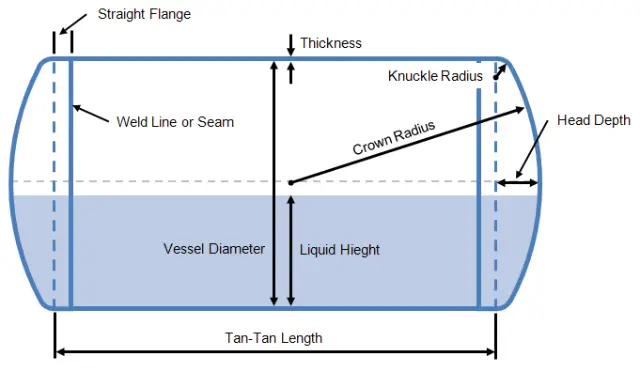

A torispherical dome consists of a spherical cap (also known as the crown), a toroidal ring around the edge (the knuckle), and a flange that allows it to be joined to the rest of the vessel (the straight flange).

Torispherical heads are usually specified by the ratio of the major radius of the torus (knuckle radius) to the minor radius (crown radius).

In a 10% torispherical head, the knuckle radius is 10% of the inner vessel diameter, and the crown radius is 10% of the inner diameter.

For a 10% torispherical head, the following formulas can be used to calculate the blank diameter (i.e., the diameter of the flat plate needed before forming) for the head.

Blank Diameter = D + 2 (0.9045 C) + (2 * SF)

Where:

- D = Inside Diameter of the Vessel

- C = Crown Radius = 0.1 * D

- SF = Straight Flange (usually about 0.35 * Crown Radius for a 10% torispherical head)

Given that the diameter of your reactor is 3000 mm,

C = 0.1 D = 0.1 3000 = 300 mm

SF = 0.35 C = 0.35 300 = 105 mm

Substituting these values into the formula:

Blank Diameter = 3000 + 2 (0.9045 300) + 2 105 = 3000 + 2 271.35 + 210 = 3752.7 mm

So, the diameter of the 12 mm thick circular plate before it can be bent to form the dish ends should be approximately 3753 mm.

This is a nominal value, and in practice the diameter might need to be adjusted slightly to account for material thickness, bending losses, and welding allowances.

Please note that these calculations are approximations and you should consult a pressure vessel design manual or a structural engineer for exact design requirements, as this can vary based on standards (like ASME) and local regulations.

Replies

-

Ramani AswathI do not think that there is any formula as such.

Ramani AswathI do not think that there is any formula as such.

There is a thumb rule used in industries. It is more an internal practice.

For shallow dishing, the diameter of the plate circle is usually the final OD of the dish plus 3 x t, where t is the thickness of the original plate. During forming a bit of the material flows from the centre towards the edges, which will give some small thickness difference over the profile. -

prashpanActually I want to calculate the weight of a reactor.

prashpanActually I want to calculate the weight of a reactor.

Now the weight of the cylinder can easily be calculated by multiplying volume X Density.

But in order to calculate the volume of top and bottom dish ends i need diameter of the plate from which they are fabricated.

Now the approx weight of such a reactor come out to be close to 8-8.5 tons.

But by my calculations it is coming out as only 4.5 tons. Even if we add gearbox, motor, nozzles etc. the difference should not be so large. -

Ramani AswathPlease see section 4.3.2.3 on torispherical dished ends. The formula for approximate volume (multiply by density for weight) is given there. Calculate the outside volume and the inside volume separately; the difference is the volume of the dished end.

Ramani AswathPlease see section 4.3.2.3 on torispherical dished ends. The formula for approximate volume (multiply by density for weight) is given there. Calculate the outside volume and the inside volume separately; the difference is the volume of the dished end.

(Pages 31-32) #-Link-Snipped-# -

mechky

mechky

See if the following relations help you in computing the correct mass:prashpanActually I want to calculate the weight of a reactor.

Now the weight of the cylinder can easily be calculated by multiplying volume X Density.

But in order to calculate the volume of top and bottom dish ends i need diameter of the plate from which they are fabricated.

Now the approx weight of such a reactor come out to be close to 8-8.5 tons.

But by my calculations it is coming out as only 4.5 tons. Even if we add gearbox, motor, nozzles etc. the difference should not be so large.

CR = Do

KR = 0.1Do

SF = 3.5t

DH = 0.1935Do – 0.455t

THi = SF + DH

Do = external head diameter

SF = straight flange height

Di = internal head diameter

DH = depth of dishing

CR = crown radius

THi = total internal head height

KR = knuckle radius

t = wall thickness

The external head diameter, 'Do' is usually equal to the outside diameter of cylindrical section.

Using these relations, prepare a solid model of the torispherical end in SolidWorks or any other software. Apply the material and then you can view its mass. Add it to the mass of cylindrical section and see if the total mass is coming out to be correct or not. This will ensure that the dimensions you are using are correct.

If the mass comes out to be correct, then only proceed with the theoretical formulae for volume calculations as they are approximate formulae and many simplified formulae give wrong answers. -

prashpanOkay, thanks for the formulae but i don't have solidworks.

prashpanOkay, thanks for the formulae but i don't have solidworks. -

prashpan

prashpan

Sir i did Calculated the volume by the formula given in the link. but by this calculation the weight is coming out as only 156.662 kgbioramaniPlease see section 4.3.2.3 on torispherical dished ends. The formula for approximate volume (multiply by density for weight) is given there. Calculate the outside volume and the inside volume separately; the difference is the volume of the dished end.

(Pages 31-32) #-Link-Snipped-#

Although the height "h" is coming as 578 mm which is correct.

Taking into consideration that R = Do for torispherical head. -

Ramani AswathI have not done the detailed calculations. To me it appears that 156 kg is probably one tenth. I got about 1.25 tons as the weight by another approximate order of magnitude calculation. Which makes the total reactor weight more like 4.5 tons, which is what you got independently.

Ramani AswathI have not done the detailed calculations. To me it appears that 156 kg is probably one tenth. I got about 1.25 tons as the weight by another approximate order of magnitude calculation. Which makes the total reactor weight more like 4.5 tons, which is what you got independently.

Have you considered the possibility that you are right? -

prashpan

prashpan

Maybe but i will only find out when the reactor is fabricated, will get back when i know the answer.bioramaniHave you considered the possibility that you are right? -

feroz khansir i want to calculate the diameter of dish to be cut for a reactor of shell having id 1000 mm & thickness 8mm.Please help me .

feroz khansir i want to calculate the diameter of dish to be cut for a reactor of shell having id 1000 mm & thickness 8mm.Please help me . -

deep.mec07can anyone tell me how to calculate the development of a dish end

deep.mec07can anyone tell me how to calculate the development of a dish end -

gaurav bhadaniblank dia of torispherical d'end is =o.d. +o.d/24 + 2/3 kr +2s.f

gaurav bhadaniblank dia of torispherical d'end is =o.d. +o.d/24 + 2/3 kr +2s.f

o.d. =outer dia of d'end

k.r = knuckle radius

s.f. = straight face

You are reading an archived discussion.