Soft Materials With Controllable Surface Textures Created Using 3D Printer

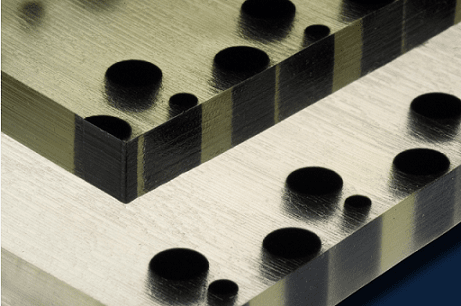

Researchers at MIT (Massachusetts Institute of Technology) have come up with a novel method of making soft composite materials with reconfigurable surface textures that can be impeccably smooth, ridged or bumpy on demand. The surface created by using a 3-D printer can alter its texture dynamically depending on the amount of pressure applied to it. The material is made up of two distinct polymers that have very different degrees of stiffness. Furthermore, the relatively hard or rigid particles were inserted in a predetermined alignment below the surface of soft elastomeric matrix of mutable material.

Upon the application of an external stimuli, the material’s surface which is initially smooth and flat changes to a particular pattern. The pattern is steered by the arrangement and shapes of the hard particles. Later, when the pressure is released, the composite material regains its original form. Thereby, the material demonstrates reversible surface properties. Instead of using round hard particles, the elongated ones can also be employed for creating surface textures that are asymmetrical. As a result, this causes the surface to have high friction on one side and slippery on another side.

According to Mark Guttag, MIT graduate student, different surface topographies such as creases, ridges, bumps and many more can be achieved along the surface by using dissimilar arrangements of the hard particles but by applying same amount of compression. Owing to the geometry driven system that depends on shapes and spacing of materials with different degrees of flexibility, the materials working on same principles with different sizes can be developed. The process can also be used for creating exceedingly complex surface textures. For instance, microfluidic channels can be developed in order to direct the movement of fluids in a chemical or biological detector.

These kind of surface textures can be used in applications such as optics, tribology, for creating surfaces that repel or attract water, camouflage, for managing the motion and turbulence of fluids, et al. The results of the research were reported in a paper which was published in the journal Advanced Functional Materials.

Source: #-Link-Snipped-# | #-Link-Snipped-#

Upon the application of an external stimuli, the material’s surface which is initially smooth and flat changes to a particular pattern. The pattern is steered by the arrangement and shapes of the hard particles. Later, when the pressure is released, the composite material regains its original form. Thereby, the material demonstrates reversible surface properties. Instead of using round hard particles, the elongated ones can also be employed for creating surface textures that are asymmetrical. As a result, this causes the surface to have high friction on one side and slippery on another side.

According to Mark Guttag, MIT graduate student, different surface topographies such as creases, ridges, bumps and many more can be achieved along the surface by using dissimilar arrangements of the hard particles but by applying same amount of compression. Owing to the geometry driven system that depends on shapes and spacing of materials with different degrees of flexibility, the materials working on same principles with different sizes can be developed. The process can also be used for creating exceedingly complex surface textures. For instance, microfluidic channels can be developed in order to direct the movement of fluids in a chemical or biological detector.

These kind of surface textures can be used in applications such as optics, tribology, for creating surfaces that repel or attract water, camouflage, for managing the motion and turbulence of fluids, et al. The results of the research were reported in a paper which was published in the journal Advanced Functional Materials.

Source: #-Link-Snipped-# | #-Link-Snipped-#

Replies

You are reading an archived discussion.

Related Posts

By analyzing the observations from the NASA's Chandra X-ray Observatory (CXO), formerly known as Advanced X-ray Astrophysics Facility (AXAF), astronomers have discovered black hole eruptions by examining the group of...

what are the role of piston, seal, boot & spring in wheel cylinder??

I've been experimenting with different DNS and wondering whether I should rely on the DNS setting on my computer or on the router? My current network setting is very typical:...

A lot many of us are not on unlimited download plans for internet. Now whenever you want to watch a video online, you either go to a video streaming site...

Micromax Canvas Hue 2 (A316 model) is the newest entrant on the block. We are looking at a Rs. 11,700 smartphone that is set to compete against the likes of...