Researchers Develop Graphene Composite To Combat Ice Buildup

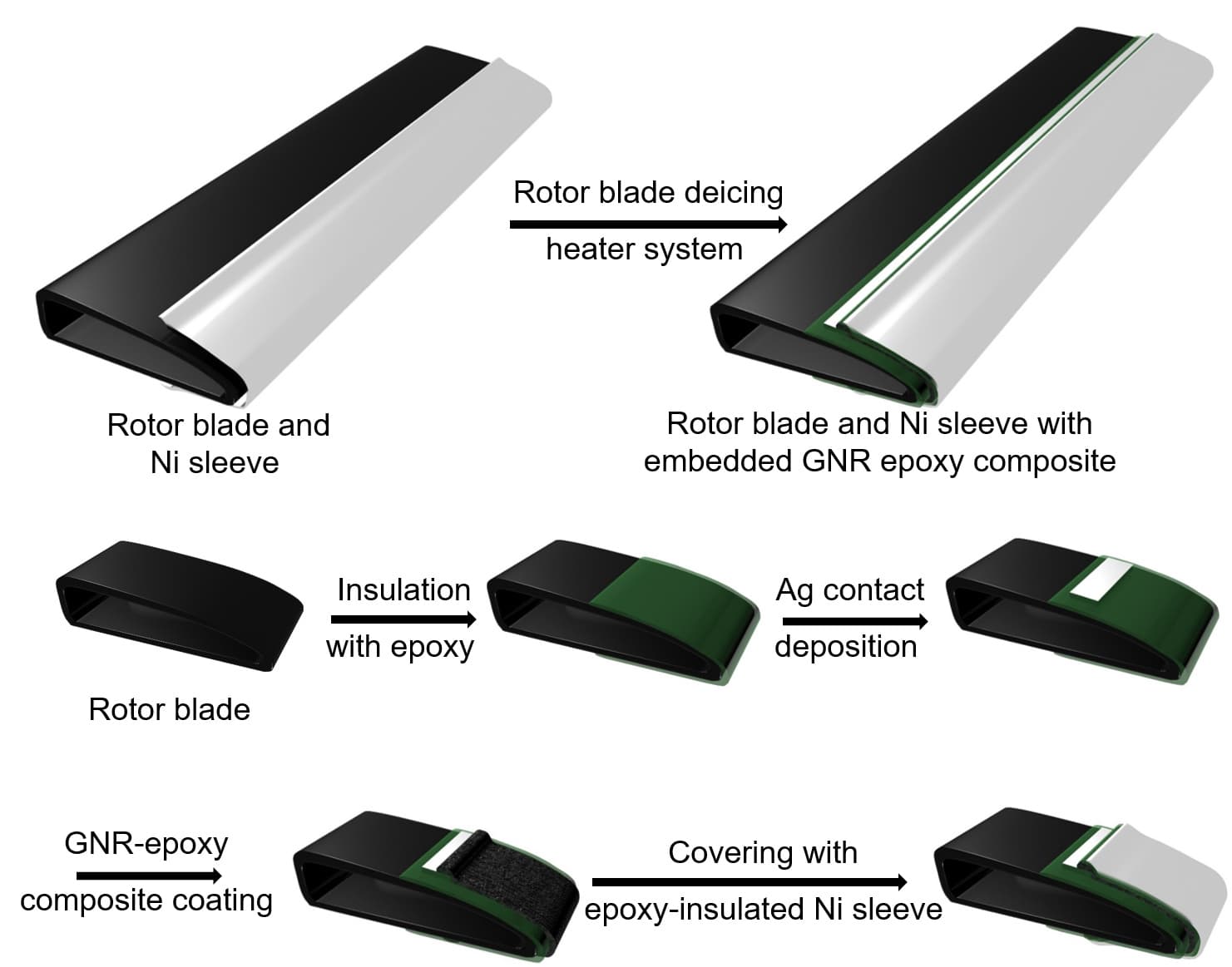

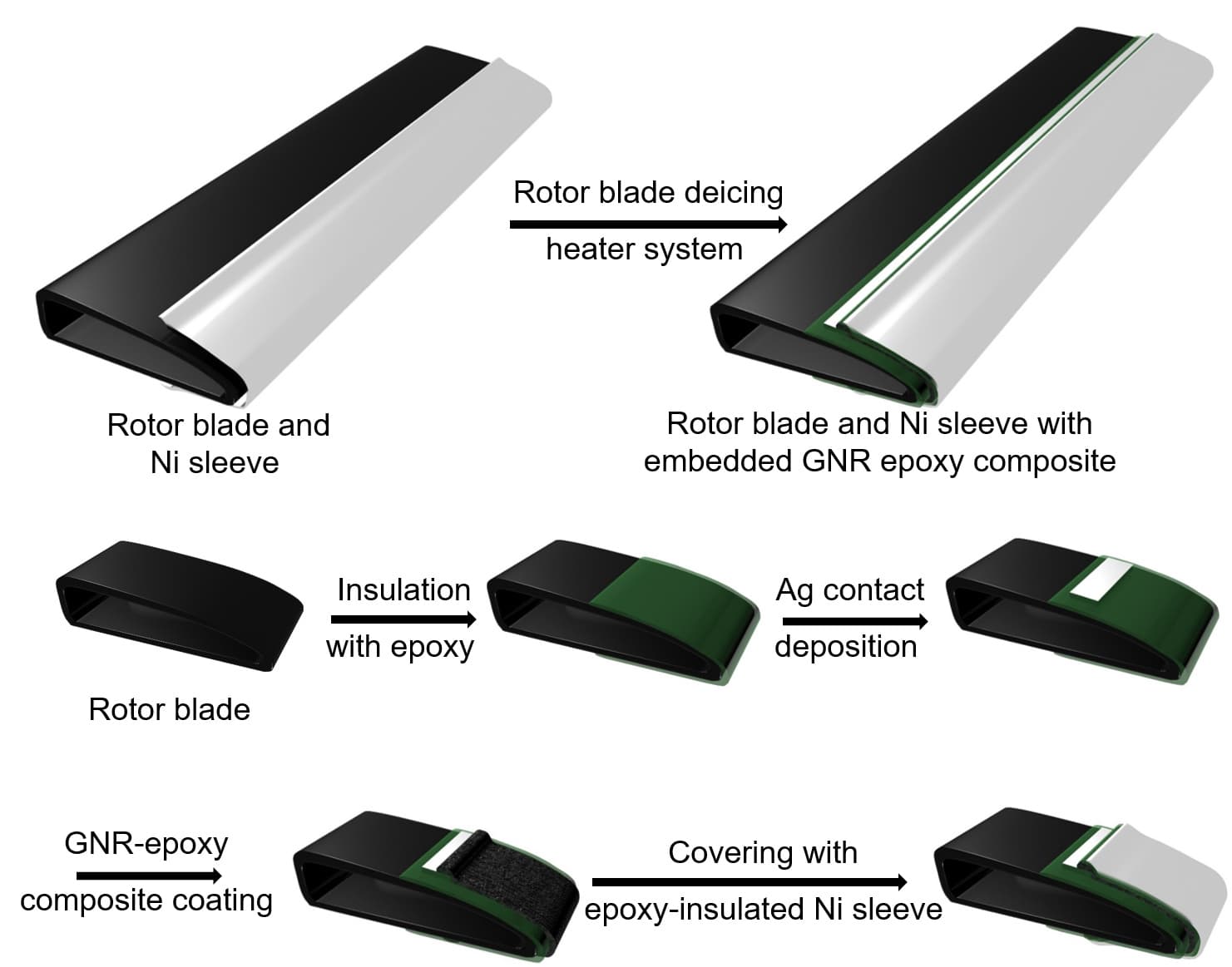

Researchers from Rice University, Texas, have developed a graphene composite that has proven very effective in melting the ice build-up on helicopter rotor blades. The material could also aid in real-time de-icing of virtually any surface, suffering from disruptive build-up of ice.

Ice build-up is a problem most often faced by aircraft, especially during severe winters. Excessive ice formation on the surface of the wings could be fatal to airplanes as the flaps could get jammed, dangerously affecting its ability to stay airborne. In helicopters, it could freeze the rotors in place. Ice could also form between circuits and freeze wires, which could also lead to unfavorable outcomes. This means that aircraft have to be methodically de-iced using processes that are time-consuming and expensive, employing chemicals that cause environmental pollution.

The researchers say that the composite material, made from graphene nano-ribbons, solves the problem of ice build-up using a process known as Joule heating. Joule heating is the process by which a material, when subjected to small voltage, produces heat. The researchers were able to heat the composite up to 200 degree Fahrenheit, which is more than enough to melt the ice formed on the surface of the material. There is also minimal chance of the heat produced damaging the material itself, as the composite can survive temperatures up to 600 degrees Fahrenheit undamaged.

The composite is transparent, and hence, can also be used on windows or any other exposed glass surfaces. Researchers say that the material could also find use on wind turbines, transmission lines, radar domes, etc.

When coated on airplanes, the composite can also act as an electromagnetic shield, providing the plane with extra protection from lightning strikes.

The material is inexpensive to manufacture and requires only a small amount of energy to work, as nano-ribbons conduct electricity way better than graphene sheets. This combined with its usefulness means that this material could be put to widespread use in the near future, in a variety of industries.

Source: #-Link-Snipped-#

Ice build-up is a problem most often faced by aircraft, especially during severe winters. Excessive ice formation on the surface of the wings could be fatal to airplanes as the flaps could get jammed, dangerously affecting its ability to stay airborne. In helicopters, it could freeze the rotors in place. Ice could also form between circuits and freeze wires, which could also lead to unfavorable outcomes. This means that aircraft have to be methodically de-iced using processes that are time-consuming and expensive, employing chemicals that cause environmental pollution.

The researchers say that the composite material, made from graphene nano-ribbons, solves the problem of ice build-up using a process known as Joule heating. Joule heating is the process by which a material, when subjected to small voltage, produces heat. The researchers were able to heat the composite up to 200 degree Fahrenheit, which is more than enough to melt the ice formed on the surface of the material. There is also minimal chance of the heat produced damaging the material itself, as the composite can survive temperatures up to 600 degrees Fahrenheit undamaged.

The composite is transparent, and hence, can also be used on windows or any other exposed glass surfaces. Researchers say that the material could also find use on wind turbines, transmission lines, radar domes, etc.

When coated on airplanes, the composite can also act as an electromagnetic shield, providing the plane with extra protection from lightning strikes.

The material is inexpensive to manufacture and requires only a small amount of energy to work, as nano-ribbons conduct electricity way better than graphene sheets. This combined with its usefulness means that this material could be put to widespread use in the near future, in a variety of industries.

Source: #-Link-Snipped-#

0