FREEZERBATON - Freezer-baton for basic cryosurgery on a budget!

I'm describing here my design and construction project of a simple tool for basic cryosurgery - limited to freezing superficial skin lesions such as verrucas and warts etc - and possibly other applications where freezing temperature needs to be applied to only a small part of a larger mass.

My tool which I have named the "FREEZERBATON" or "Freezer-baton" employs a preparatory step of temporarily cooling parts of the disassembled freezer-baton in a domestic food-freezer before a simple assembly prior to applying the tool tip to the spot that needs freezing.

The freezer-baton has a feature to counter-act the inevitable tendency of a solid tool tip to be warmed by the patient's skin and the environment - an encapsulated water / anti-freeze solution which draws warmth away from the tool tip, effectively when mixed by effortlessly and intermittently inverting the freezer-baton, glugging an air-bubble within the solution up and down within the encapsulated volume.

When the freezer-baton has inevitably warmed through to the core and therefore has become ineffective for freezing anything, it can be disassembled and returned to the domestic food-freezer for re-cooling for later re-use.

A freezer-baton like this can be manufactured from off-the-shelf parts available from a DIY or plumbing supplies shop.

The following photographs of my freezer-baton should provide enough familiar information for a skilled plumber or anyone with a DIY aptitude and experience to make something similar.

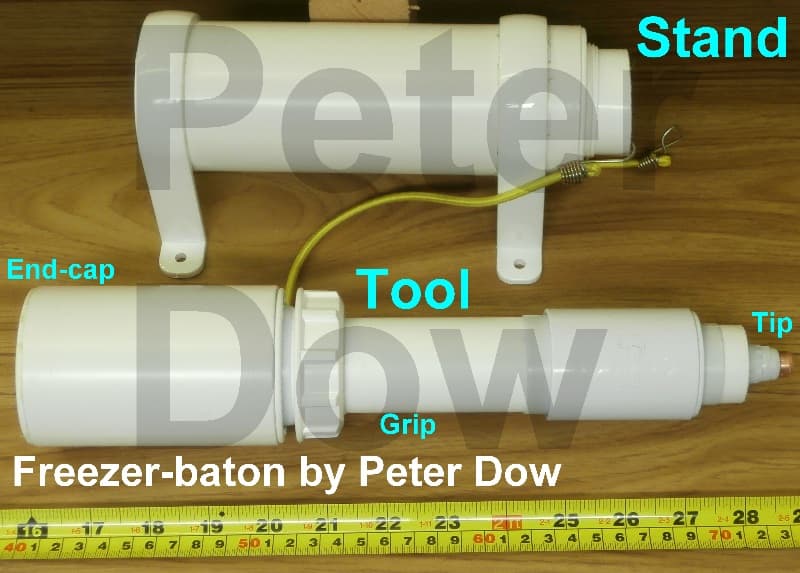

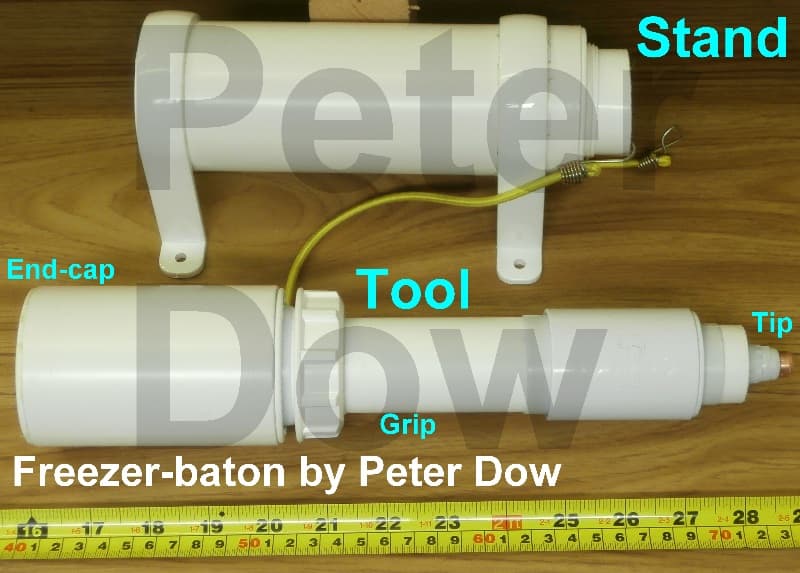

Freezer-baton by Peter Dow

![[IMG]](proxy.php?image=http%3A%2F%2Fscot.tk%2Fforum%2Fmedia%2Ffreezerbatonpeterdow_A_800.jpg&hash=e7dabb49b6ccdada8e27deedcef47eb6)

Alternative image link #-Link-Snipped-#

Freezer-baton secured to go with carry-case bungee cords. Weight 1068 g

![[IMG]](proxy.php?image=http%3A%2F%2Fscot.tk%2Fforum%2Fmedia%2Ffreezerbatonpeterdow_B_800.jpg&hash=d707ad24b1b8b0c3cfd88ddc92a69cb5)

Alternative image link #-Link-Snipped-#

Unhooking the bungee cords from one end of the freezer-baton carry-case allows the tool to slide out of the stand.

![[IMG]](proxy.php?image=http%3A%2F%2Fscot.tk%2Fforum%2Fmedia%2Ffreezerbatonpeterdow_C_800.jpg&hash=5844f6e835e690eca25e3bbe2fa4e4d3)

Alternative image link #-Link-Snipped-#

Freezer-baton unboxed - Stand (258 g) & Tool (810 g) (showing tool end-cap, grip & tip)

![[IMG]](proxy.php?image=http%3A%2F%2Fscot.tk%2Fforum%2Fmedia%2Ffreezerbatonpeterdow_D_800.jpg&hash=b08639ffaa586d28ce55c3a28fb71f18)

Alternative image link #-Link-Snipped-#

Tool disassembles for quicker cooling. 1. End-cap pulls off, 2. Nut unscrews, 3. Grip pulls off. Showing tool end-grip revealed when the end-cap is pulled off

Compare and contrast the freezer-baton with established cryosurgery tools

Even simpler and lower-cost for the occasion use are the verruca & wart remover freezing aerosol kits one can buy from the chemist, which use dimethyl-ether - propane.

<a href="https://en.wikipedia.org/wiki/Cryosurgery#Dimethyl_ether_.E2.80.93_propane" target="_blank" rel="nofollow noopener noreferrer">Cryosurgery Dimethyl Ether .E2.80.93 Propane</a>

However those kits have a strictly limited number of applications before the aerosol runs out. Also, a cold liquid which might drip or run is harder to control than a cold solid.

The freezer-baton never runs out of chemicals and my food freezer is on all the time anyway so there's little or no additional running costs of cooling a freezer-baton when I need to.

On the other hand, a freezer-baton is not a sufficiently powerful and flexible tool to compete with the type of high-tech, high-cost cryo-surgery probes which a modern hospital can afford.

So I would not claim that my design is a breakthrough in medical science and engineering that will sweep all competition aside.

Rather my freezer-baton design is more the kind of design which one might have expected to have seen bodged together for a Scrapheap Challenge or a student project maybe!

I had made my first prototype of this cryosurgery tool minus the plastic parts and had insulated it with only pipe insulating foam a few years ago but although it seemed to work OK, because it wasn't doing anything new that other existing tools couldn't do just as well or better, I didn't see any great urgency in publishing anything about it at the time.

Now that I've completed this second tool (because I lost the first tool) and this time I've also designed and made the plastic insulation, grip and stand, I think it may be worth publishing this brief project report?

My tool which I have named the "FREEZERBATON" or "Freezer-baton" employs a preparatory step of temporarily cooling parts of the disassembled freezer-baton in a domestic food-freezer before a simple assembly prior to applying the tool tip to the spot that needs freezing.

The freezer-baton has a feature to counter-act the inevitable tendency of a solid tool tip to be warmed by the patient's skin and the environment - an encapsulated water / anti-freeze solution which draws warmth away from the tool tip, effectively when mixed by effortlessly and intermittently inverting the freezer-baton, glugging an air-bubble within the solution up and down within the encapsulated volume.

When the freezer-baton has inevitably warmed through to the core and therefore has become ineffective for freezing anything, it can be disassembled and returned to the domestic food-freezer for re-cooling for later re-use.

A freezer-baton like this can be manufactured from off-the-shelf parts available from a DIY or plumbing supplies shop.

The following photographs of my freezer-baton should provide enough familiar information for a skilled plumber or anyone with a DIY aptitude and experience to make something similar.

Freezer-baton by Peter Dow

![[IMG]](proxy.php?image=http%3A%2F%2Fscot.tk%2Fforum%2Fmedia%2Ffreezerbatonpeterdow_A_800.jpg&hash=e7dabb49b6ccdada8e27deedcef47eb6)

Alternative image link #-Link-Snipped-#

Freezer-baton secured to go with carry-case bungee cords. Weight 1068 g

![[IMG]](proxy.php?image=http%3A%2F%2Fscot.tk%2Fforum%2Fmedia%2Ffreezerbatonpeterdow_B_800.jpg&hash=d707ad24b1b8b0c3cfd88ddc92a69cb5)

Alternative image link #-Link-Snipped-#

Unhooking the bungee cords from one end of the freezer-baton carry-case allows the tool to slide out of the stand.

![[IMG]](proxy.php?image=http%3A%2F%2Fscot.tk%2Fforum%2Fmedia%2Ffreezerbatonpeterdow_C_800.jpg&hash=5844f6e835e690eca25e3bbe2fa4e4d3)

Alternative image link #-Link-Snipped-#

Freezer-baton unboxed - Stand (258 g) & Tool (810 g) (showing tool end-cap, grip & tip)

![[IMG]](proxy.php?image=http%3A%2F%2Fscot.tk%2Fforum%2Fmedia%2Ffreezerbatonpeterdow_D_800.jpg&hash=b08639ffaa586d28ce55c3a28fb71f18)

Alternative image link #-Link-Snipped-#

Tool disassembles for quicker cooling. 1. End-cap pulls off, 2. Nut unscrews, 3. Grip pulls off. Showing tool end-grip revealed when the end-cap is pulled off

Compare and contrast the freezer-baton with established cryosurgery tools

Even simpler and lower-cost for the occasion use are the verruca & wart remover freezing aerosol kits one can buy from the chemist, which use dimethyl-ether - propane.

<a href="https://en.wikipedia.org/wiki/Cryosurgery#Dimethyl_ether_.E2.80.93_propane" target="_blank" rel="nofollow noopener noreferrer">Cryosurgery Dimethyl Ether .E2.80.93 Propane</a>

However those kits have a strictly limited number of applications before the aerosol runs out. Also, a cold liquid which might drip or run is harder to control than a cold solid.

The freezer-baton never runs out of chemicals and my food freezer is on all the time anyway so there's little or no additional running costs of cooling a freezer-baton when I need to.

On the other hand, a freezer-baton is not a sufficiently powerful and flexible tool to compete with the type of high-tech, high-cost cryo-surgery probes which a modern hospital can afford.

So I would not claim that my design is a breakthrough in medical science and engineering that will sweep all competition aside.

Rather my freezer-baton design is more the kind of design which one might have expected to have seen bodged together for a Scrapheap Challenge or a student project maybe!

I had made my first prototype of this cryosurgery tool minus the plastic parts and had insulated it with only pipe insulating foam a few years ago but although it seemed to work OK, because it wasn't doing anything new that other existing tools couldn't do just as well or better, I didn't see any great urgency in publishing anything about it at the time.

Now that I've completed this second tool (because I lost the first tool) and this time I've also designed and made the plastic insulation, grip and stand, I think it may be worth publishing this brief project report?

0