3D Nano-walls May Significantly Improve Touchscreen Experience

Scientists from the ETH Zurich University have developed transparent electrodes , for use in touch screens which have the potential to revolutionize the 'touch' experience in contemporary electronic gadgets. These 'new' type of electrodes are manufactured using a 3D printng technology that takes the form of a grid made of gold or silver 'nanowalls' on a glass surface. At present, all touch enabled screens are made of transparent electrodes which are barely visible to the human eye and are created using a conductive material. These touchscreen can sense almost anything that carries an electric charge, including the human skin.

The research team led by Professor of Thermodynamics, Dimos Poulikakos, created for the first time, a thin transparent conductive material made of gold and silver by using the three dimensional printing technology. The resultant material provided a more transparent and conductive material compared to the present day touchscreens which are made of Indium Tin Oxide (a ternary composition of indium, tin and oxygen in varying proportions). The present research was a success as transparency and conductivity are directly proportional to the screen quality and precision respectively.

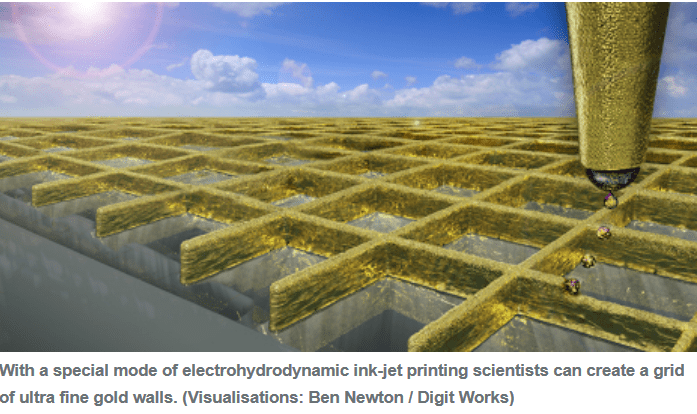

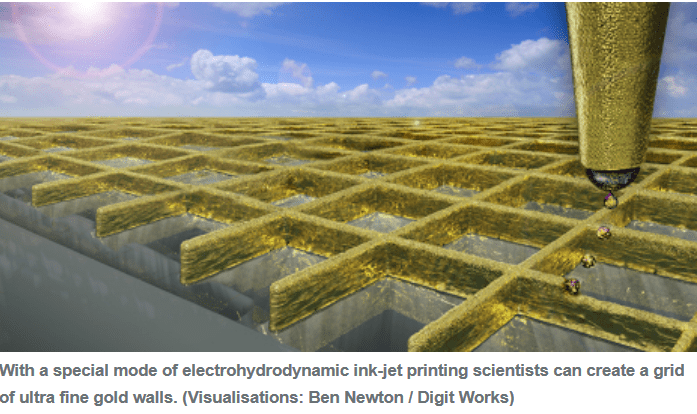

Patrik Rohner, a PhD student in Poulikakos’ team explained that modern touchscreens which are made of ITO are moderately conductive and compromise considerably with the screen quality. To increase the conductivity, gold and silver were chosen but they they lagged in transparency. Finally, they created a 80 to 500 nanometre thick gold and silver grid designed by the help of a 3D Ink-jet printer, making use of the electro hydrodynamic ink-jet printing technology. The printing process, dubbed as “Nanodripâ€, was specially outlined to obtain only the nanoscaled material composed of metallic ink from the capillary, and accumulate it drop by drop on the grid.

The team have also promised to upgrade the current printing process in such a way, so that it could be commercially viable . In its quest, they have started working with the ETH spin-off company named Scrona. Once released, it is expected to replace current ITO screens. 3D printed Carbon Nanotubes May Help Detect Rare Proteins And Viruses also have the potential to be an alternative component of modern transparent electrodes in Solar cells and the OLED display technology.

Source: #-Link-Snipped-#

The research team led by Professor of Thermodynamics, Dimos Poulikakos, created for the first time, a thin transparent conductive material made of gold and silver by using the three dimensional printing technology. The resultant material provided a more transparent and conductive material compared to the present day touchscreens which are made of Indium Tin Oxide (a ternary composition of indium, tin and oxygen in varying proportions). The present research was a success as transparency and conductivity are directly proportional to the screen quality and precision respectively.

Patrik Rohner, a PhD student in Poulikakos’ team explained that modern touchscreens which are made of ITO are moderately conductive and compromise considerably with the screen quality. To increase the conductivity, gold and silver were chosen but they they lagged in transparency. Finally, they created a 80 to 500 nanometre thick gold and silver grid designed by the help of a 3D Ink-jet printer, making use of the electro hydrodynamic ink-jet printing technology. The printing process, dubbed as “Nanodripâ€, was specially outlined to obtain only the nanoscaled material composed of metallic ink from the capillary, and accumulate it drop by drop on the grid.

The team have also promised to upgrade the current printing process in such a way, so that it could be commercially viable . In its quest, they have started working with the ETH spin-off company named Scrona. Once released, it is expected to replace current ITO screens. 3D printed Carbon Nanotubes May Help Detect Rare Proteins And Viruses also have the potential to be an alternative component of modern transparent electrodes in Solar cells and the OLED display technology.

Source: #-Link-Snipped-#

Replies

You are reading an archived discussion.

Related Posts

Hi Sir/Madam,

I want to do diploma in Big data analytical from C-DAC but i am 2012 pass out student and still i am fresher so that i am scared...

it is usually considered that iit's mostly provide us with great opportunities. Is the scope of a normal engineering student doing something big very less in india?

Nikon gave shutterbugs a good time at the CES this year by announcing 3 top of the line cameras including Nikon D5,which is the sequel to its already popular D4....

University of Virginia Center for Diabetes Technology Director Boris Kovatchev has been working with his team of researchers on an artificial pancreas arrangement system since 2006. With assistance from Francis...

The practical things a civil engineering student should know depends on the future plans of the student after completing his/her graduation.

Most undergrads are recruited by construction companies in the...